Even though some carbon fiber can handle 400–500°C, it’s still far below the 1500°C inside an aircraft engine, keeping metal forging essential. Key parts in programs like LEAP and CFM56, such as turbine disks and compressor shafts that rely on forged nickel and titanium alloys. Stratview Research reports that engine components account for over 70% of the aircraft forging market, exceeding $17 billion as of April 2025.

In today’s aerospace landscape, both composites and additive manufacturing keep capturing headlines for their weight savings and design freedom quite frequently. While composites deliver ultralight parts with high strength, 3D printing enables topology-optimized, high-precision components with minimal waste. Yet beneath these cutting-edge methods lies a process, unchanged for centuries: forging. From the blacksmith’s hammer and anvil to today’s multi-thousand-ton presses, forged parts have been able to maintain their share in aerospace manufacturing because of their still superior characteristics, like the optimal grain flow they can achieve and the exceptional fatigue resistance they offer.

Thus, despite not being as light as composite parts and not as precise as the 3D-printed ones, forged components still find several applications in aerospace, specifically in areas where parts with low complexity and high fatigue resistance are required. Though the rapid uptake of composites and Metal AM processes have indeed substituted many traditional forgings like wing spars, fuselage frames, floor beams, etc.; which now often come as carbon-fiber assemblies rather than forged aluminum, the forgings market in aerospace has remained resilient and still presents a $20+ bn addressable market as of 2025, according to Stratview Research.

Aircraft Engines Still Being the ‘Hot’ Market:

Traditionally, forged parts formed the backbone of both an aircraft’s primary structure and its propulsion system. But with the advent of high-performance polymer matrix composites (PMCs), many structural components (mostly in areas where service temperatures rarely exceed the 100-150°C range) gradually migrated to CFRPs, offering weight savings and corrosion resistance.

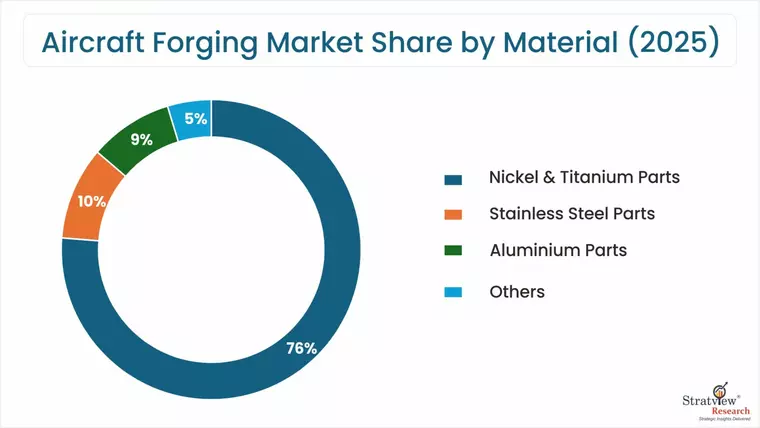

The critical area, however, that still remains unconquered by PMCs is the inside of the aircraft’s engine. Though several aerospace-grade carbon fiber suppliers claim a temperature tolerance range of 400-500°C in their offerings, the specified range, even if fulfilled, would still fall short of the tolerance required inside an aircraft’s engine, where the temperatures can exceed 1500°C. This limitation has preserved forging’s dominance in engines, where metal superalloys withstand punishing heat, pressure, and cyclic stresses. Engine components like turbine disks, compressor shafts, spinners, etc., in almost all popular engine programs like the LEAP and the CFM56 use forged parts. According to Stratview Research, >70% of the aircraft forging market is confined to the engines alone. As of April 2025, this would translate to a market size of $17+ bn for engine forgings alone, a majority (~70%) of which will be met by parts made of nickel and titanium alloys.

Fig 1: Market Share of Aircraft Forging Materials in 2025

One of the emerging substitutes for metal-forged components in engines, however, are Ceramic Matrix Composites or CMCs. CMCs are tough, lightweight, and?capable of withstanding temperatures 300–400 degrees F hotter than metal alloys. Because of factors like lower impact resistance, manufacturing complexity, and costs, their applications are currently limited to static parts only. Popular engines like the LEAP currently incorporate a single CMC component (a turbine shroud) as compared to hundreds of forged components. In 2025, the market for CMCs in aircraft engines is expected to be ~$300 million, which is <10% of the market for aircraft engine forgings.

Shaping the Future Demand:

Increasing aircraft deliveries globally is going to be the biggest organic growth driver for the aircraft forgings market. Leading aircraft OEM, Airbus, estimates more than 40,000 global commercial aircraft deliveries to take place in the next 20 years, which is roughly ~2000 aircraft per year, and which is also in line with leading aircraft manufacturer Safran’s estimate of delivering 2000 leap engines in the year 2026. Additionally, the increasing intensity of the regulatory authorities will drive the preference towards forged components over casted components. In general, forged parts have ~25% higher tensile strength, 30% higher fatigue strength, and up to 45% higher yield strength as compared to their casted counterparts.

These superior characteristics, combined with the ever-rising demand for its end-use application, i.e., aircraft, are expected to drive the aircraft market beyond $30 bn by 2028, as per estimates. In short, as engines grow hotter and the skies become busier, this ancient craft quietly forges aviation’s future – one grain-aligned turbine disk at a time.

Authored by Stratview Research. Also published on – Aluminium Journal

.jpg)

.jpg)