The majority of innovations today are closely linked to automation, which is enhancing efficiency and redefining possibilities across various industries. When we talk about automation, it’s natural for robotics to come to mind. Robots are visible, dynamic, and often at the center of the conversation about innovation. But beneath every robot’s movement, and every automated process lies something less tangible but equally essential, their brain – their software, that serves as the backbone of their functionality, transforming initial concepts into fully realized solutions.

Robot software is everything from – simple scripts to complex systems, that utilize disruptive technologies, including Artificial Intelligence (AI) and Machine Learning (ML) to control communication between robots and other systems, manage algorithms, and provide real-time monitoring and performance optimization. In short, it enables robots to operate according to the given commands, essentially transforming a mechanical device into a functional, autonomous system capable of carrying out specific actions without constant human intervention.

Today, robots are everywhere, making significant impacts across various sectors as the demand for automation in different sectors grows. From autonomous drones and robotic arms in factories to medical robots, humanoid robots, smart home bots, and AI-powered service bots, robot software is the underlying force that drives robotic systems.

Robot manufacturing includes several steps. Once the hardware elements – including controllers, sensors, actuators, motors, etc. for the robot have been selected, the focus shifts to the software framework. Software for a robot consists of tools, and standards designed for development and the deployment of robotic systems. Various types of software are integral to robotics development.

their movements.

(Robot Operating System), provides a framework for running and managing complex robotic systems from a single unified interface.

HMI (Human-Machine Interface), SCADA (Supervisory Control and Data Acquisition), etc. are a few among them.

Selecting suitable software for a robot depends on different criteria, compatibility with robot hardware, budget constraints, resources, skill level of the team, etc. Popular frameworks such as ROS, Microsoft Robotics Studio, Player, Orocos, Gazebo, etc. are commonly used tools that cater to various aspects of robotic development.

Key Applications of Robot Software

The software that powers any robot, be it industrial or service, is crucial for functionality, enabling the robots to perform complex tasks autonomously and interact seamlessly with human operators and other systems.

Designed to operate in varied environments such as homes, hospitals, and hotels, service robots require software that enables them to perform tasks alongside humans requiring features like speech recognition and gesture detection, allowing them to adapt to dynamic situations and user needs. A few widely used service robots are da Vinci by Intuitive Surgical, and Spot by Boston Dynamics, etc.

In contrast, industrial robots are primarily deployed in controlled manufacturing settings where they perform repetitive tasks like welding, painting, assembly, material handling, etc. Their software typically focuses on precision control and efficiency, often utilizing real-time operating systems to ensure the timely execution of predefined tasks. Industrial robots generally operate autonomously with minimal human interaction, relying on specialized programming tailored to specific applications. FANUC LR Mate 200iD, ABB IRB 460, KUKA KR AGILUS, Universal Robots UR10e, etc., are a few of them.

In short, be it robotaxis, humanoids, smart home devices, automated logistics, healthcare, finance, etc., every industry demands software for a perfectly functioning robot.

However, the growing trend of industrial automation globally presents significant opportunities for robot software in the industrial sector. The International Federation of Robotics (IFR) states that in 2023 alone over 541,000 industrial robots were newly installed globally, bringing the total operational stock of industrial robots to an all-time high in number to > 4.3 million.

IFR also predicts that the industrial robots’ annual installation count could go as high as 602000 units by 2027.

Asian Industrial Revolution Powers the Robot Software Market

The Asia-Pacific (APAC) region is considered to be the economic powerhouse, generating increased demand for labor-saving technologies across industries, making it the largest region with a high demand for industrial robots.

Nearly 70% of the total newly deployed robots installed in 2023 were in Asia as per IFR.

With over 50% of all industrial robots installed in 2023, China – the global leader in absolute terms, is by far the world’s largest market with >276,200 industrial robots installed in 2023.

Robot density also serves as a barometer for measuring the level of automation adoption across industries, emphasizing the increasing demand for robot software in countries that are rapidly embracing automation.

Fig. Robot Density in the Manufacturing Industry 2023 (Source – International Federation of Robotics)

The top three countries where the robot fleet per worker is high are Korea, Singapore, and China, with 1,012, 770, and 470 robots installed per 10,000 workers, respectively, in 2023. Additionally, while Germany ranks fourth with significant adoption, Japan follows closely in fifth place (with 419 robots installed per 10000 workers – 10 less than Germany), further emphasizing the strong presence of APAC countries in the robotics landscape.

The growing robot fleet highlights the increasing adoption of intelligent robotic solutions, powered by advanced software that not just optimizes operations but also addresses workforce challenges, enabling organizations to leverage data-driven insights for improved decision-making and productivity.

Performance Optimizers for the Robot Software –

During the 20th century, many of us imagined that robots would be an essential part of everyday life by the year 2000. However, this vision did not come to pass for several reasons, with a lack of technological advancement being one of the most crucial factors.

The rise of new technologies such as artificial intelligence (AI), Machine Learning (ML), and advanced sensors started powering sophisticated robotic applications. The world is automating faster than ever, and to meet this demand, the need for robots and robot software to drive automated systems is on the rise. Robot manufacturing giants are rapidly upgrading their software and collaborating with other firms to match the shift.

For instance, in October 2024, Formant, a cloud robotics management software provider partnered with Slalom – a global consulting firm, to enhance automation adoption in enterprises. Their collaboration also focuses on providing expert guidance and support to ensure seamless deployment and integration of robotics software with existing systems.

To simplify the usage of robots in the medical field, new software has been developed by researchers from the School of Biomedical Engineering & Imaging Sciences. They have integrated KUKA’s Fast Robot Interface (FRI) with ROS2 and Python significantly enhancing the capabilities of surgical robots for providing support for both simulation and real hardware communication.

Programming an industrial robot can take weeks to months. Jacobi Robotics has pioneered a new kind of AI-powered motion planning technology that requires 1000x less computational time and enables the deployment of robots in less than one day.

In December 2024, ABB Robotics, a key player in the robot software market, announced advancements in robotic capabilities by integrating AI and generative AI, to enable robots to understand natural language, navigate complex environments, and learn tasks from videos. With such advancements in technology and software, robots will gradually evolve into ‘robotic colleagues’ that can adapt to human interactions and learn new skills as they work alongside humans in the near future.

The Future –

Many studies state that the world’s biggest economies will eventually experience labor shortages. Also, current trends show that the world is aging gradually, requiring assistance in healthcare or monitoring, etc.

Whether it’s addressing labor shortages, enhanced productivity without fatigue, improved quality and consistency in production, better workplace safety by handling hazardous tasks, or optimized floor space utilization, robots are here to help.

The adoption of robotics is a real industry process that requires a number of pieces to fall into place. Robust software is one of the vital criteria for any robot manufacturing company to look upon. The robotics industry is filled with tales of companies that have shut down, one of the reasons being faulty or delayed software updates.

A prime example is READY Robotics, founded in 2016, best known for its ForgeOS robot-agnostic operating system, which had to shut down. Amongst various reasons – delayed software update was the one, that was needed to be implemented immediately but took months to be done.

Apart from this, also there lies a challenge that acts as a pothole in the growing robot software market – the data security concern that is rising with the rise in connected bots, and systems. Since the industry has adopted robotics systems faster than it has embraced cybersecurity practices, it is prone to cyber-attacks.

Apart from this, also there lies a challenge that acts as a pothole in the growing robot software market – the data security concern that is rising with the rise in connected bots, and systems. Since the industry has adopted robotics systems faster than it has embraced cybersecurity practices, it is prone to cyber-attacks.

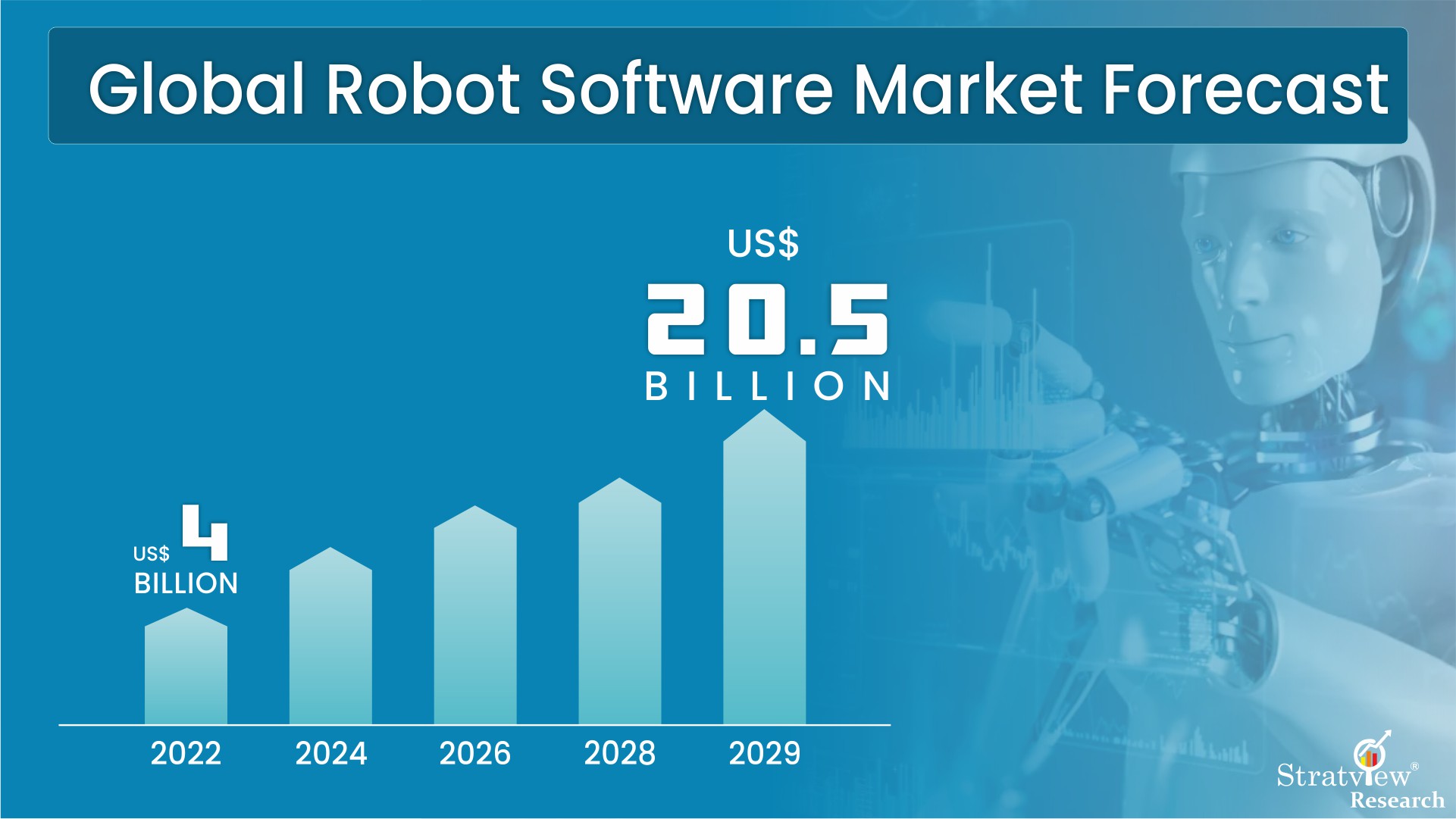

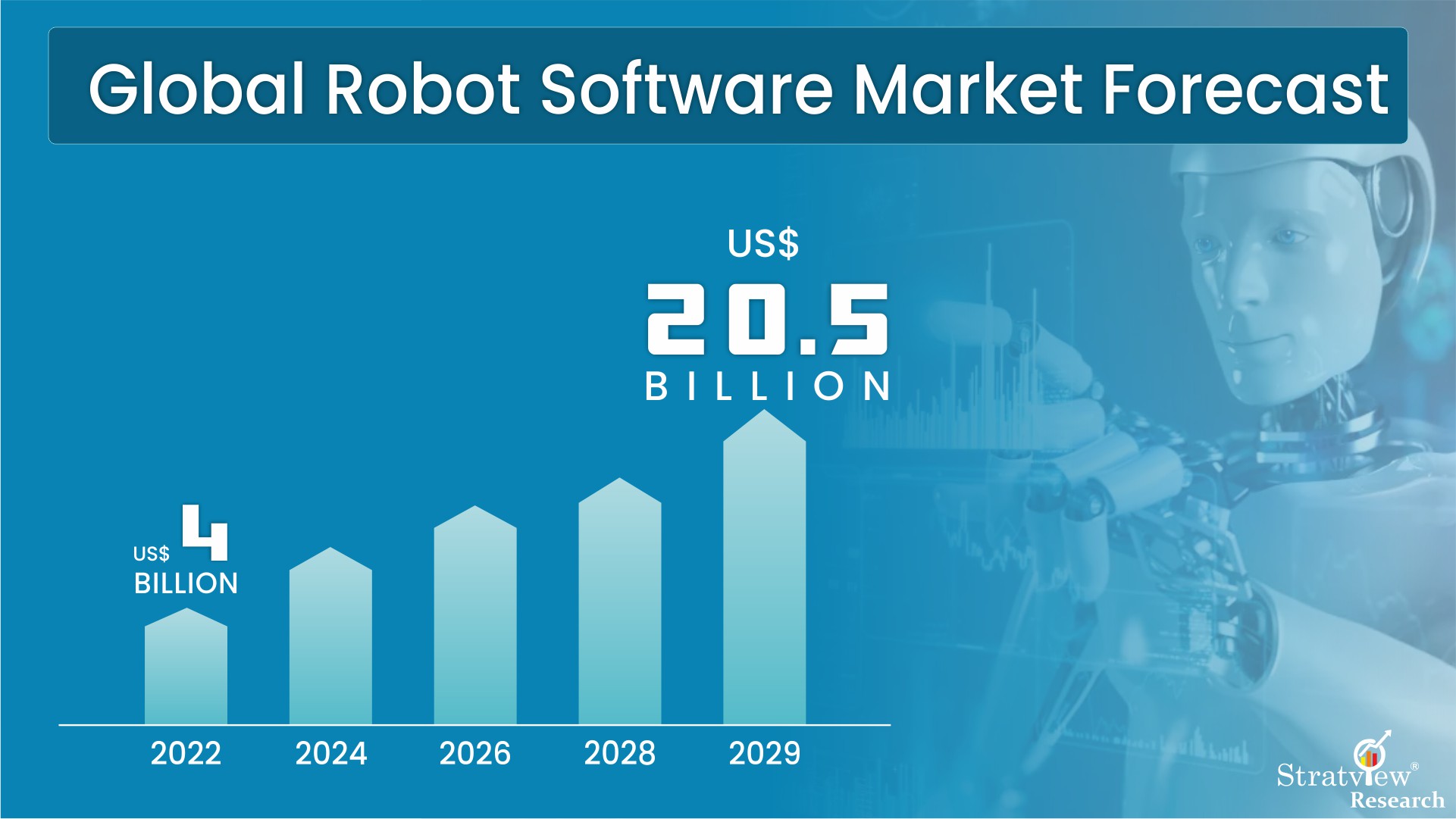

Despite obstacles, the reliance on automation and increasing integration of robotics in various industries continues to drive growth in the robotics software market. The global Robot Software Market is projected to grow ~5 times, expanding from >USD 4 billion in 2022 to >USD 20.5 billion by 2029, reflecting a remarkable growth.

As industries embrace automation and smart manufacturing, the demand for sophisticated robotic solutions will continue to surge, paving the way for innovative robotic software.