3D Printing Powder Market Insights

“The global 3D printing powder market size was US$ 1.7 billion in 2024 and is likely to grow at a decent CAGR of 24.9 % in the long run to reach US$ 8.2 billion in 2031.”

Introduction

3D printing powder, also known as additive manufacturing powder, refers to a material that is used in powder bed fusion, as ink in the 3D printing method. It is made of fine metal, ceramic, or polymer particles that are used to construct three-dimensional things, layer by layer. In powder-based 3D printing, individual powder particles are bound through controlled emission of energy. The energy can be either a laser, a narrow beam of UV light, or an electron beam. Metal, plastics, and ceramics are three significant types of powder used in 3D printing techniques. The powder is spread into thin layers, and a heat source or binder selectively solidifies the design, producing highly detailed, strong, and complex geometries.

3D printing powder is witnessing growing usage across various industries due to its ability to produce complex, lightweight, and high-strength components with minimal material waste. Applications of 3D printing technology are expanding rapidly in aerospace, automotive, healthcare, and industrial manufacturing, where there is rising demand for custom parts, rapid prototyping, and on-demand production. The shift toward sustainable and efficient production methods further boosts the adoption of 3D printing powders globally.

3D Printing Powder Market Drivers

The 3D printing powder market is driven by increasing demand for lightweight, high-strength components across aerospace, automotive, and medical industries. Advancements in powder metallurgy and material innovations are further accelerating adoption, enhancing part performance and production efficiency. Additionally, the growing trend of mass customization and rapid prototyping is boosting the use of 3D printing powders, especially metal and ceramic-based variants.

Segments' Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High-Growth Opportunity

|

|

Material-Type Analysis

|

Metal, Plastics, and Ceramics

|

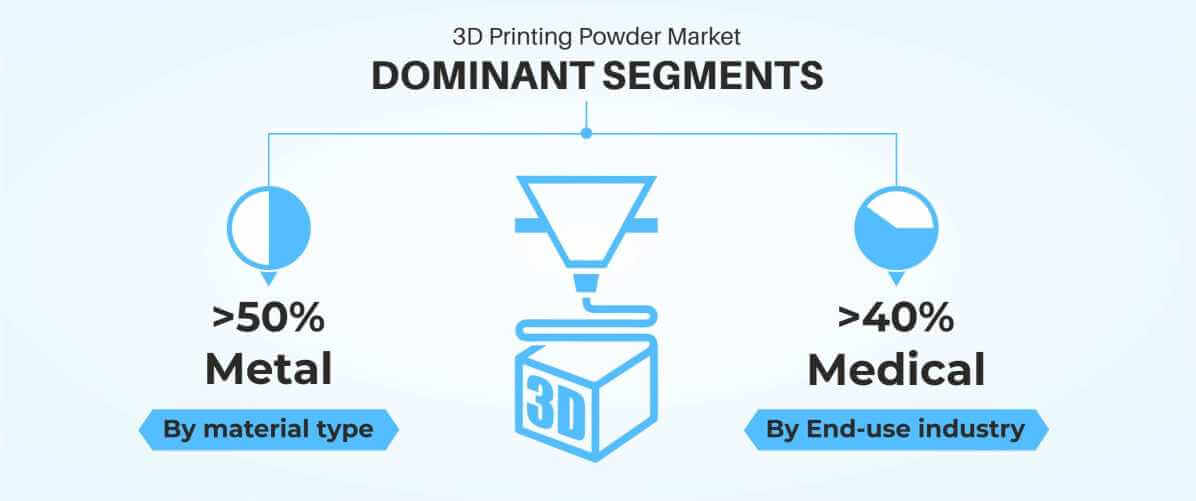

Metal is expected to maintain its dominance and continue to lead the market. The plastic material category is expected to remain the second largest during the forecast period.

|

|

Metal-Type Analysis

|

Steel, Nickel Alloys, Titanium Alloys, Aluminum Alloys, Cobalt Alloys, and Other Metals

|

Titanium alloys are expected to maintain their dominance and are also likely to be the fastest-growing metal type over the years.

|

|

End-Use Industry-Type Analysis

|

Aerospace & Defense, Medical, Automotive, Energy, and Other End-Use Industries

|

Medical is anticipated to remain dominant, whereas aerospace & defense will be the fastest-growing end-use industry over the years.

|

|

Region Analysis

|

North America, Europe, Asia-Pacific, and The Rest of the World

|

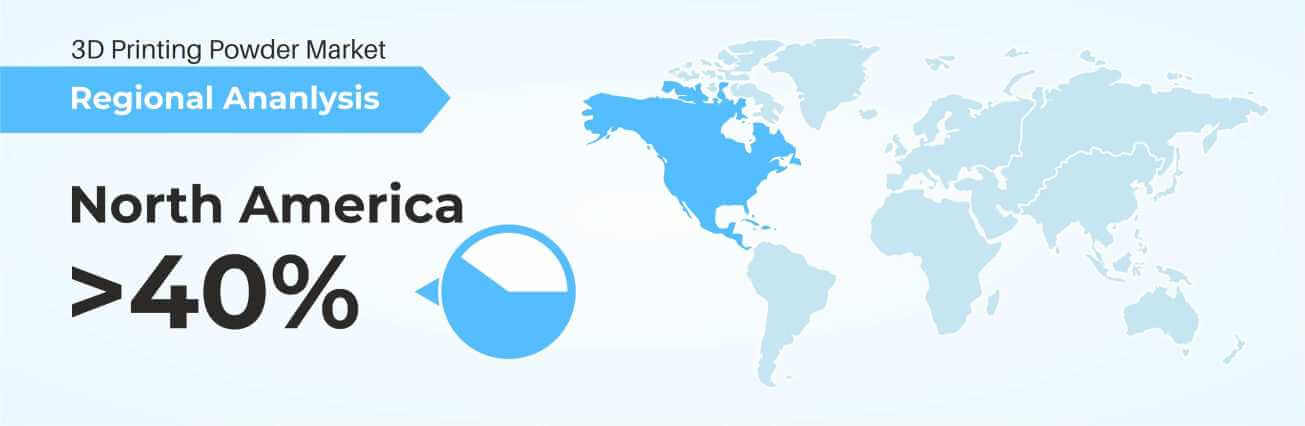

North America is expected to remain the dominant region for the 3D-printing powder market during the forecast period.

|

Material Insights

“Metal holds the dominant market position and is expected to continue to lead the market during the forecasted period.”

Based on the material type, the 3D printing powder market is segmented into metal, plastics, and ceramics. Easy to manufacture complex parts, manufacture precise and highly detailed objects, high strength and hardness with very low weight, and less material wastage are key advantages of metal 3D printing. The key metal powder characteristics are particle size distribution, smooth, regular-shaped metal powder particles, good flowability, and optimum packing density.

Plastics (polymer) offer impact and chemical resistance; excellent elasticity and ductility; very high mechanical and thermal properties, such as high rigidity, extremely solid even at very low temperatures, and stress resistance. Polyamide and polyetherketoneketone (PEKK) are key polymer types used.

Metal Insights

"The titanium alloy is estimated to remain the largest metal of the market in the coming years."

Based on the metal type, the market is segmented into steel, nickel alloys, titanium alloys, aluminum alloys, cobalt alloys, and other metals. Titanium alloy is estimated to remain the most dominant metal type in the market till 2031. Titanium alloys are preferred for applications that require significant weight saving while maintaining high performance in end-use industries, such as aerospace, medical, automotive, and engineering industries. Titanium alloys are also likely to have the most impressive growth trajectory during the forecast period.

Want to get a free sample? Register Here

End-Use Industry Insights

“The medical segment emerged as the leading contributor to the market.”

Among the end-use industry types, the market is segmented into aerospace & defense, medical, automotive, energy, and other end-use industries. Medical is expected to remain the largest end-use industry, key applications are surgical implants (e.g., cranial plates or hip joints), external prostheses, dental crowns & bridges, and removable partial dentures. It is also used in the manufacturing of pharmaceutical drug formulations for clinical trials (small batch size).

Aerospace & Defense is likely to remain the second-largest market by 2031. Key applications are lightweight brackets, structural components, airframe fasteners, engine mounts, turbine blades, fuel nozzles, and compressor inlet temperature sensors.

Regional Insights

“North America is estimated to maintain its dominance in the years to come. Asia-Pacific is likely to experience the fastest growth over the same period."

In terms of region, the market is segmented into North America, Europe, Asia-Pacific, and the Rest of the World. The USA is the largest 3D printing powder market with the presence of major hardware, material, and software manufacturers in the country. The presence of key players in the region, such as GE Aerospace, Carpenter Technology Corporation, Tekna, Praxair Technology, Inc., and ATI, is likely to stir the region’s demand.

Asia-Pacific is likely to grow at the fastest pace in the market over the next six years. China, Japan, and India are among the key countries in the Asia-Pacific region to adopt 3D printing technology. China is one of the leading countries in the 3D printing powder market owing to huge investment by the Chinese government, early adoption, large-scale utilization, and rapid development.

Want to get a free sample? Register Here

Key Players

The market is fragmented with the presence of less than 100 global and regional players. Some of the major players also manufacture 3D printing metal parts. Leading players hold excellent market positions with a vast product portfolio, a wide distribution network, and years of track record. The following are the key players in the 3D printing powder market.

Here is the list of the Top Players (Based on Dominance)

-

GKN Powder Metallurgy (A Melrose Plc Company)

-

GE Aerospace

-

ATI

-

Carpenter Technology Corporation

-

BASF 3D Printing Solutions Company (A BASF SE Company)

-

Sandvik AB

-

Oerlikon

-

Hoganas AB

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Please write to us at [email protected]

Recent Developments of 3D Printing Powder Market

A considerable number of strategic alliances, including M&As, JVs, etc., have been performed over the past few years:

-

In 2018, Carpenter Technology Corporation acquired LPW Technology for an enterprise value of US$ 81 million. LPW Technology is a manufacturer of ultra-clean metal powders for 3D printing. Metal powders are developed for the powder bed fusion process and optimized for a specific machine type.

-

In 2018, Hoganas AB acquired the Surface Technology & Ceramic Powders GmbH division of H.C. Strack. The acquisition expanded Hognas AB’s footprint in surface coating and additive manufacturing markets.

-

In 2021, EOS acquired a stake in Metalpine GmbH, which is a metal powder manufacturer based in Graz, Austria. The acquisition was to jointly develop innovative and sustainable metal powders.

-

In December 2022, Amaero International Limited signed a joint venture agreement with Rabdan Industries for additive manufacturing and powder production in Abu Dhabi, UAE. The joint venture company, FALCON Advanced Metals PLC, will be a 50/50 partnership between the two companies and will act as a holding company.

Report Features

This report provides market intelligence most comprehensively. The report structure has been kept so that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market. The following are the key features of the report:

-

Market structure: Overview, industry life cycle analysis, supply chain analysis.

-

Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

-

Market trend and forecast analysis.

-

Market segment trend and forecast.

-

Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

-

COVID-19 impact and its recovery curve.

-

Attractive market segments and associated growth opportunities.

-

Emerging trends.

-

Strategic growth opportunities for the existing and new players.

-

Key success factors.

Market Segmentation

The 3D printing powder market is segmented into the following categories:

By Material Type

By Metal Type

-

Steel Alloys

-

Nickel Alloys

-

Titanium Alloys

-

Cobalt Alloys

-

Other Metals

By End-User Type

-

Aerospace & Defence

-

Medical

-

Automotive

-

Energy

-

Other End-Use Industries

By Region

-

North America (Country Analysis: The USA, Canada, and Mexico)

-

Europe (Country Analysis: Germany, France, The UK, Russia, and the Rest of Europe)

-

Asia-Pacific (Country Analysis: Japan, China, India, and Rest of Asia-Pacific)

Research Methodology

This strategic assessment report, from Stratview Research, provides a comprehensive analysis that reflects today’s 3D printing powder market realities and future market possibilities for the forecast period. The report segments and analyzes the market in the most detailed manner to provide a panoramic view of the market. The vital data/information provided in the report can play a crucial role for the market participants as well as investors in the identification of the low-hanging fruits available in the market as well as to formulate the growth strategies to expedite their growth process.

This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools. More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data. We conducted more than 8 detailed primary interviews with the market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respectable clients:

Company Profiling

Competitive Benchmarking

-

Benchmarking of key players on the following parameters: Product portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview Research offers custom research services across sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to [email protected].