Attractive Opportunities

Global Demand Analysis & Sales Opportunities in Electrolyzer PEM Membrane Market

-

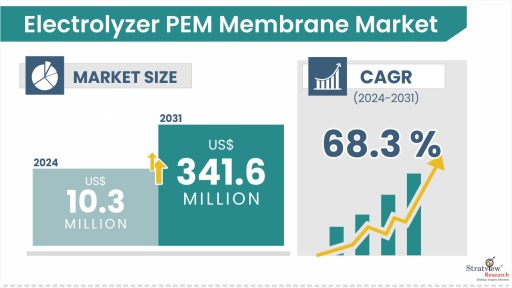

The annual demand for electrolyzer PEM membrane was USD 10.3 million in 2024 and is expected to reach USD 15.0 million in 2025, up 45.6% than the value in 2024.

-

During the forecast period (2025-2031), the electrolyzer PEM membrane market is expected to grow at a CAGR of 68.3%. The annual demand will reach USD 341.6 million in 2031, which is almost 22 times the demand in 2025.

-

During 2025-2031, the electrolyzer PEM membrane industry is expected to generate a cumulative sales opportunity of USD 817.4 million.

Want to get a free sample? Register Here

High-Growth Market Segments:

-

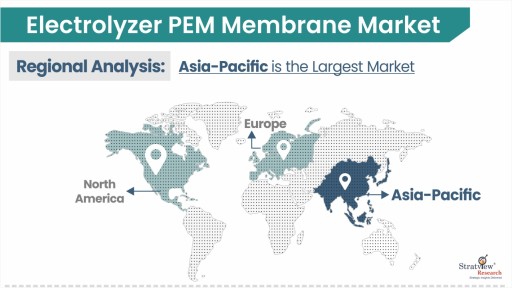

Asia-Pacific region is expected to dominate the market over the forecast period and is also expected to grow at the fastest pace.

-

By end-use type, Transportation is anticipated to be the largest end-use industry contributing to the growth of the PEM membrane.

-

By membrane material type, Perfluorosulfonic acid materials have dominated the market in the past and will continue to reign in the forecast period.

Market Statistics

Have a look at the sales opportunities presented by the electrolyzer PEM membrane market in terms of growth and market forecast.

|

Electrolyzer PEM Membrane Market Data & Statistics

|

|

|

Market Statistics

|

Value (in USD Million)

|

Market Growth (%)

|

|

Annual Market Size in 2024

|

USD 10.3 million

|

-

|

|

Annual Market Size in 2025

|

USD 15.0 million

|

YoY Growth in 2025: 45.6%

|

|

Annual Market Size in 2031

|

USD 341.6 million

|

CAGR 2025-2031: 68.3%

|

|

Cumulative Sales Opportunity during 2025-2031

|

USD 817.4 million

|

-

|

|

Top 10 Countries’ Market Share in 2024

|

USD 8.2 million +

|

> 80%

|

|

Top 10 Company’s Market Share in 2024

|

USD 5.1 million to USD 7.2 million

|

50% - 70%

|

Market Dynamics

Introduction:

A Proton Exchange Membrane (PEM) is a crucial component in PEM electrolyzers, facilitating the separation of hydrogen and oxygen during water electrolysis. Made of a solid polymer electrolyte, it allows protons to pass while blocking gases, ensuring efficient hydrogen production. The membrane's high proton conductivity, chemical stability, and low gas permeability in PEM electrolyzers enhance efficiency and durability. Its ability to operate at high current densities and respond quickly to load changes makes it ideal for green hydrogen production. Recent developments focus on improving membrane durability, reducing costs, and enhancing performance. Researchers are exploring reinforced membranes, fluoropolymer alternatives, and nano-coatings to minimize degradation. Ionomer advancements and bipolar plate modifications also contribute to efficiency gains. These innovations are crucial for scaling up green hydrogen production for renewable energy integration and decarbonization efforts.

Market Drivers:

-

The rising demand for PEM electrolyzer membranes is driven by the increasing need for green hydrogen, which is becoming a key solution for decarbonization in industries such as transportation, power generation, and heavy manufacturing. Government policies, including carbon neutrality targets, subsidies, and financial incentives, are further accelerating investments in hydrogen production, directly influencing the expansion of high-performance PEM membranes. Advancements in technology, such as reinforced membranes, ionomer innovations, and nano-coatings, are enhancing durability, efficiency, and cost-effectiveness, making PEM electrolyzers commercially viable on a larger scale.

-

Additionally, the declining costs of renewable energy sources like solar and wind are lowering the overall cost of hydrogen production through electrolysis, creating greater market opportunities. The increasing adoption of hydrogen in industrial applications, including steelmaking, ammonia synthesis, and chemical production, further drives the demand for high-efficiency PEM membranes. Moreover, hydrogen’s role as an energy storage medium and grid stabilizer is gaining traction, boosting the PEM electrolyzer market. As governments and industries prioritize clean energy solutions, the demand for next-generation PEM membranes is set to grow exponentially, shaping the future of hydrogen production.

Market Challenges:

-

The market growth will face challenges due to expensive production and the nondegradable nature of PFSA material, which affects the environment.

-

The current manufacturing process is complex and hence limits mass production, while limited hydrogen infrastructure affects the electrolyzer adoption.

-

Raw material availability creates supply chain vulnerabilities, affecting scalability. Competition from alternative energy sources, such as lithium-ion batteries, also hinders market growth.

Segment Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High-Growth Opportunity

|

|

End-Use Type Analysis

|

Transportation, Chemicals, Refinery Bio & Synfuels, Power, Iron & Steel, and Other End-Uses.

|

Transportation is anticipated to be the largest end-use industry contributing to the growth of the PEM membrane. The rise of fuel cells in mobility will contribute to the growth of the PEM electrolyzer and its membrane market.

|

|

Membrane Material-Type Analysis

|

Perfluorosulfonic Acid, Partially Fluorinated Polymer, Non-Fluorinated Polymer, and Composite Materials, and Other Membrane Materials

|

Perfluorosulfonic acid materials have dominated the market in the past and will continue to reign in the forecast period.

|

|

Region Analysis

|

North America, Europe, Asia-Pacific, and The Rest of the World

|

The Asia-Pacific region is expected to dominate the market over the forecast period and is also expected to grow at the fastest pace.

|

End-Use Insights

“Transportation is expected to be the dominant end-use segment driving the growth of electrolyzer PEM membranes, with the surging adoption of fuel cells in mobility playing a key role in boosting demand for PEM electrolyzers and their membranes.”

-

The market is segmented into transportation, chemicals, refueling bio & synfuels, power, iron & steel, and other end-uses by end-use type. by application type.

-

The transportation sector is set to be the leading driver of PEM membrane demand, fueled by the growing adoption of fuel cell technology. Fuel Cell Electric Vehicles (FCEVs), including cars, buses, trucks, and trains, rely on hydrogen-powered fuel cells for efficient and zero-emission transportation. This, in turn, increases the demand for PEM electrolyzers that produce hydrogen via water electrolysis, making high-performance PEM membranes essential. The shift toward hydrogen mobility is driven by the need to decarbonize transportation, one of the largest contributors to global carbon emissions. Unlike battery-electric vehicles, which face limitations in refueling times and driving ranges, hydrogen fuel cells offer rapid refueling and extended ranges, making them ideal for heavy-duty and long-haul applications.

-

Governments worldwide are supporting hydrogen mobility through incentives, infrastructure investments, and carbon reduction policies, further accelerating PEM electrolyzer adoption. Furthermore, continuous advancements in PEM membrane technology, enhancing durability, efficiency, and affordability, are making hydrogen fuel cells increasingly viable for large-scale transportation. This interconnected growth of fuel cell mobility and PEM electrolyzers will significantly propel the PEM membrane market forward.

Membrane Material Insights

“Perfluorosulfonic acid materials have long led the market, and they're on track to maintain their dominance well into the forecast period.”

-

The market is segmented into perfluorosulfonic acid, partially fluorinated polymer, non-fluorinated polymer, composite materials, and other membrane materials by membrane material type.

-

Perfluorosulfonic acid (PFSA) materials have been the leading choice for PEM electrolyzer membranes due to their outstanding chemical stability, high proton conductivity, and low gas permeability. These characteristics enable PFSA-based membranes to facilitate efficient proton transfer while minimizing hydrogen and oxygen crossover, ensuring safe and effective hydrogen production. Their proven durability in harsh electrochemical environments has solidified their position as the industry standard for PEM electrolyzers.

-

PFSA membranes are essential for improving electrolyzer efficiency, reliability, and lifespan. Their ability to withstand high current densities and adapt to fluctuating operating conditions makes them ideal for large-scale hydrogen production. Additionally, their superior thermal and mechanical stability is crucial for sustained performance in demanding industrial applications.

-

Ongoing advancements in PFSA technology aim to enhance efficiency while lowering costs. Researchers are exploring innovations such as reinforced PFSA membranes, hybrid structures, and nano-coatings to improve durability and reduce degradation. Additionally, refinements in ionomer structures are being pursued to further boost proton conductivity. Given these continuous developments and PFSA’s well-established reliability, they are expected to maintain their dominance in the electrolyzer PEM membrane market for years to come.

Regional Insights

“The Asia-Pacific region is expected to dominate the market over the forecast period and is also estimated to grow at the fastest pace.”

-

The market is segmented into North America, Europe, Asia-Pacific, and the Rest of the World by region type. The Asia-Pacific region is expected to dominate the PEM electrolyzer membrane market in the future, experiencing the highest growth. While Europe and North America currently lead the market due to their early adoption of hydrogen technologies, robust government policies, and significant investments in green hydrogen infrastructure, the Asia-Pacific region is rapidly catching up and is set to surpass these regions in the coming years.

-

Several factors contribute to this anticipated shift. Countries like China, Japan, South Korea, and India are making substantial investments in hydrogen production and electrolyzer technology as part of their long-term energy transition strategies. China, in particular, has laid out ambitious hydrogen roadmaps and is scaling up its electrolyzer manufacturing capabilities, positioning itself as a major driver of global market growth. Japan and South Korea are also at the forefront of adopting hydrogen fuel cells, especially in transportation and power generation.

-

Moreover, the Asia-Pacific region benefits from cost advantages, including proximity to raw materials, economies of scale from large production facilities, and strong government incentives. The region's rapidly expanding industrial sector and growing demand for clean energy technologies further accelerate the need for high-performance PEM membranes.

-

As renewable energy sources like solar and wind become more cost-competitive in the region, hydrogen production through electrolysis is becoming increasingly viable, driving large-scale deployment of PEM electrolyzers. With continued policy support, technological innovations, and swift infrastructure development, the Asia-Pacific region is set to outpace other regions and emerge as the global leader in the electrolyzer PEM membrane market.

Want to get a free sample? Register Here

Competitive Landscape

The market is consolidated, with major players holding a significant portion of the market. Most of the major players compete in some of the governing factors, including price, product offerings, regional presence, etc. The following are the key players in the electrolyzer PEM membrane market.

Here is the list of the Top Players (Based on Dominance)

-

Chemours

-

W.L. Gore & Associates

-

BASF SE

-

Ballard Power Systems

-

3M

-

Fumatech BWT GmbH

-

Toray Industries

-

DuPont de Nemours, Inc.

-

Dongyue Group

-

Asahi Kasei Corporation

-

Solvay S.A.

-

AGC Chemicals

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Please write to us at [email protected]

Recent Developments

Recent Market JVs and Acquisitions:

The recent mergers and acquisitions in the market are driven by the need for advanced materials, the supply chain strengthening, and reducing production costs.

Recent Product Development:

-

In 2023, a group of researchers from Japan, led by Professor Kenji Miyatake from Waseda University and the University of Yamanashi, synthesized novel proton-conductive membranes using a partially fluorinated aromatic ionomer. The membrane tests indicate it is chemically more stable, durable, and thermally resistant than any other material.

-

In 2022, Researchers developed composite Nafion membranes by incorporating materials like polydopamine and its derivatives. These composites show improved thermal and mechanical stability, along with enhanced proton conductivity and reduced hydrogen permeability.

Report Features

This report provides market intelligence most comprehensively. The report structure has been kept so that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market.

The following are the key features of the report:

-

Market structure: Overview, industry life cycle analysis, supply chain analysis.

-

Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

-

Market trend and forecast analysis.

-

Market segment trend and forecast.

-

Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

-

COVID-19 impact and its recovery curve.

-

Attractive market segments and associated growth opportunities.

-

Emerging trends.

-

Strategic growth opportunities for the existing and new players.

-

Key success factors.

|

Market Study Period

|

2019-2031

|

|

Base Year

|

2024

|

|

Forecast Period

|

2025-2031

|

|

Trend Period

|

2019-2023

|

|

Number of Tables & Figures

|

>100

|

|

Number of Segments Analysed

|

3 (End-Use Type, Membrane Material Type, and Region)

|

|

Number of Regions Analysed

|

4 (North America, Europe, Asia-Pacific, Rest of the World)

|

|

Countries Analysed

|

15 (The USA, Canada, Mexico, Germany, France, Italy, The UK, China, Japan, India, Brazil, Saudi Arabia, Rest of Europe, Rest of APAC, and Rest of the World)

|

|

Free Customization Offered

|

10%

|

|

After Sales Support

|

Unlimited

|

|

Report Presentation

|

Complimentary

|

|

Market Dataset

|

Complimentary

|

|

Further Deep Dive & Consulting Services

|

10% Discount

|

Market Segmentation

The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The global electrolyzer PEM membrane market is segmented into the following categories:

Electrolyzer PEM Membrane Market, by End-Use Type

-

Transportation

-

Chemicals

-

Refinery Bio & Synfuels

-

Power

-

Iron & Steel

-

Other End-Uses

Electrolyzer PEM Membrane Market, by Membrane Material Type

Electrolyzer PEM Membrane Market, by Region

-

North America (Country Analysis: The USA, Canada, and Mexico)

-

Europe (Country Analysis: Germany, France, Austria, and Rest of Europe)

-

Asia-Pacific (Country Analysis: Japan, China, South Korea, India, and Rest of Asia-Pacific)

-

Rest of the World (Country Analysis: Brazil, Saudi Arabia, and Others)

Research Methodology

-

This strategic assessment report from Stratview Research provides a comprehensive analysis that reflects today’s electrolyzer PEM membrane market realities and future market possibilities for the forecast period.

-

The report segments and analyzes the market in the most detailed manner to provide a panoramic view of the market.

-

The vital data/information provided in the report can play a crucial role for market participants and investors in identifying the low-hanging fruits available in the market and formulating growth strategies to expedite their growth process.

-

This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools.

-

More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data.

-

We conducted more than 15 detailed primary interviews with market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respected clients:

Company Profiling

Competitive Benchmarking

-

Benchmarking of key players on the following parameters: Product portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview Research offers custom research services across industries. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to [email protected]