Alkaline Electrolyzer Stack Systems Market Insights

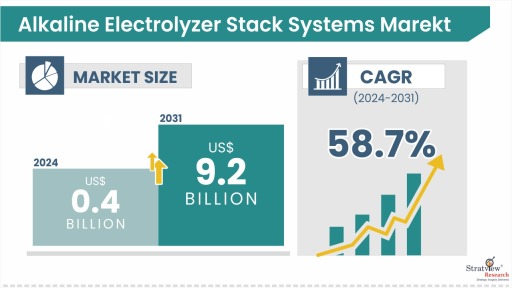

“The global alkaline electrolyzer stack systems market size was 2.2 GW by volume, and US$ 0.4 billion by value in 2024 and is likely to grow at an impressive CAGR of 63.6% to reach 60.8 GW by volume, and a CAGR of 58.7% to reach US$ 9.2 billion in 2031.”

Want to get a free sample? Register Here

Introduction

Alkaline electrolyzer stack systems have been a fundamental part of hydrogen technology, evolving from basic industrial applications into advanced, high-efficiency systems capable of large-scale green hydrogen production. From their early use with simple alkaline electrolyte solutions, these systems have significantly improved in efficiency, durability, and scalability. The Technology Readiness Level (TRL) of alkaline electrolyzers has advanced considerably, reaching commercial maturity and being widely adopted in industries such as ammonia production, steel manufacturing, and energy storage. Unlike early models with lower current densities and higher maintenance requirements, modern alkaline electrolyzers feature enhanced electrode materials, improved diaphragms, and automated control systems, resulting in greater reliability and cost-effectiveness. Their role in the hydrogen economy is further strengthened by their ability to provide a stable and continuous hydrogen supply at a lower capital cost compared to Proton Exchange Membrane (PEM) electrolyzers. As ongoing research enhances their adaptability to renewable energy integration and dynamic operational capabilities, alkaline electrolyzer stack systems continue to be a key technology for global hydrogen production, supporting the transition to a decarbonized energy future.

Alkaline Electrolyzer Stack Systems Drivers

Several key factors drive the growth of the alkaline electrolyzer stack systems market, primarily their lower capital costs compared to Proton Exchange Membrane (PEM) electrolyzers, making them the preferred choice for large-scale hydrogen production. Alkaline electrolyzers utilize cost-effective and widely available materials like nickel-based catalysts instead of expensive platinum-group metals, significantly reducing production expenses. Advancements in technology have also enhanced their efficiency, durability, and ability to operate at higher current densities, further strengthening their role in the hydrogen economy. A major factor contributing to their expansion is their increasing compatibility with renewable energy sources such as wind and solar power. While traditionally designed for steady-state operation, recent innovations have improved their flexibility, allowing them to better handle variable power inputs and integrate more effectively with renewable energy systems. Governments and industries worldwide are also investing heavily in green hydrogen initiatives, implementing policies, incentives, and subsidies that encourage the adoption of alkaline electrolyzers. Their scalability makes them ideal for industrial applications such as ammonia production, refining, and steel manufacturing, where large hydrogen volumes are required. With ongoing research improving their efficiency and operational adaptability, alkaline electrolyzers are set to play a crucial role in meeting the growing global demand for cost-effective and sustainable hydrogen production.

Market Challenges

Despite the increasing adoption of alkaline electrolyzer stack systems, several challenges hinder their widespread market growth. One major limitation is their lower operational flexibility compared to Proton Exchange Membrane (PEM) electrolyzers. Another key challenge is their lower current density and efficiency than PEM electrolyzers, resulting in higher electricity consumption per unit of hydrogen produced. Additionally, alkaline electrolyzers rely on a liquid electrolyte, typically potassium hydroxide, which introduces maintenance complexities, safety concerns, and the risk of leakage. Scaling up production and deployment is also challenging, as large-scale alkaline electrolyzer plants require significant space and infrastructure.

Segment Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High-Growth Opportunity

|

|

Power-Supply Type Analysis

|

Renewable Energy, Grid, and Other Power Supplies

|

Renewable energy has dominated the market, with the grid and other power supplies also holding significant market shares. Renewable energy is expected to lead the market in the coming years, with technology supporting the flexible operations of alkaline electrolyzer stack systems.

|

|

End-Use-Type Analysis

|

Transportation, Chemicals, Refinery & Synfuels, Power, Iron & Steel, and Other End-Uses

|

Chemicals are anticipated to contribute as the largest end-use, as mass hydrogen synthesized by an alkaline electrolyzer stack synced with methanol and ammonia production will boost the market.

|

|

Region Analysis

|

North America, Europe, Asia-Pacific, and The Rest of the World

|

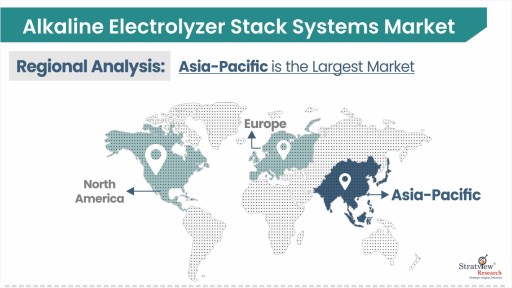

The Asia-Pacific region is expected to dominate the market in the forecast period and is likely to grow at the fastest rate.

|

Power-Supply Insights

“Renewable energy continues to lead the market, supported by flexible alkaline electrolyzer technologies, while grid and other power sources hold strong shares. This dominance is expected to strengthen in the coming years.”

The alkaline electrolyzer stack systems market is segmented into renewable energy, grid, and other power supplies. Renewable energy has emerged as the primary power source for alkaline electrolyzer stack systems, playing a crucial role in advancing clean hydrogen production. With governments worldwide pushing for carbon neutrality, large-scale investments in solar and wind energy have surged, positioning renewable energy as the preferred choice for powering electrolyzers. While grid electricity and other power sources still hold a notable share, the declining cost of renewables and advancements in electrolyzer technology are strengthening their integration. Traditionally, alkaline electrolyzers were best suited for continuous power input, but technological innovations are enhancing their ability to operate efficiently with variable renewable energy sources. These improvements enable alkaline electrolyzers to better manage fluctuations in solar and wind power while maintaining stable hydrogen production. Supportive policies, financial incentives, and the increasing demand for hydrogen in industrial and energy industries ensure that renewable energy will continue to dominate as the leading power source for alkaline electrolyzers, driving market expansion in the coming years.

End-Use Insights

“The chemical industry is expected to dominate end-use demand, as large-scale hydrogen production from alkaline electrolyzer stacks, aligned with methanol and ammonia synthesis, drives significant market growth.”

The alkaline electrolyzer stack systems market is segmented into transportation, chemicals, refinery & synfuels, power, iron & steel, and other end-uses by end-use type. The chemical industry is projected to be the largest end-user of alkaline electrolyzer stack systems due to its significant hydrogen demand for ammonia and methanol production. Ammonia, a crucial component in fertilizers, and methanol, widely used in industrial chemicals and fuels, require a large-scale hydrogen supply. Traditionally, this hydrogen has been sourced from fossil fuel-based processes like steam methane reforming (SMR), which contributes to high carbon emissions. However, with the global push toward industrial decarbonization and green hydrogen adoption, alkaline electrolyzers have emerged as a promising solution for sustainable hydrogen production. Their cost-effectiveness, scalability, and ability to produce high hydrogen volumes make them well-suited for integration into ammonia and methanol plants. Governments worldwide are supporting the shift to green hydrogen through incentives and regulatory frameworks, accelerating the transition. As industries increasingly seek cleaner alternatives to meet sustainability goals, the demand for electrolyzer-generated hydrogen in the chemical industries will continue to grow, establishing it as the dominant consumer of alkaline electrolyzer stack systems.

Regional Insights

“The Asia-Pacific region is poised to lead the market throughout the forecast period, with growth projected to surge at the fastest pace globally.”

The Asia-Pacific region is expected to lead and grow at the fastest pace, driven by strong industrial demand, supportive government policies, and rapid advancements in hydrogen infrastructure. Countries such as China, Japan, South Korea, and India are making significant investments in green hydrogen production to support industries like chemicals, refining, and steel manufacturing, all of which require a large-scale hydrogen supply. China has positioned itself as a global leader in electrolyzer manufacturing, benefiting from lower production costs, a robust supply chain, and extensive renewable energy deployment. Japan and South Korea are also actively advancing their hydrogen economies, focusing on ammonia production and hydrogen fuel applications, which further boost demand for alkaline electrolyzers. Governments in the region are introducing incentives, subsidies, and regulatory frameworks to accelerate the shift toward green hydrogen, further driving market expansion. With abundant renewable energy resources, expanding hydrogen infrastructure, and increasing collaboration between public and private projects, the Asia-Pacific region is set to surpass other regions in alkaline electrolyzer adoption, fueling market growth in the forecast period.

Want to get a free sample? Register Here

Key players

The market is fragmented, with multiple players supplying either a particular component or complete stack systems solutions. Most of the major players compete in some of the governing factors, including price, product offerings, regional presence, etc. The following are the key players in the alkaline electrolyzer stack systems market.

Here is the list of the Top Players (Based on Dominance)

-

LONGi Green Energy Technology Co., Ltd.

-

Thyssenkrupp AG

-

NEL ASA

-

Cummins Inc. (Hydrogenics)

-

Asahi Kasei Corporation

-

McPhy Energy S.A.

-

Green Hydrogen Systems

-

Stargate Hydrogen

-

HydrogenPro

-

John Cockerill Group

-

Hitachi Zosen Corporation

-

Suzhou Jingli Hydrogen Production Equipment Co., Ltd.

-

Tianjin Mainland Hydrogen Equipment Co., Ltd.

-

Kumatec Hydrogen GmbH

-

Shanghai Zhizhen Green Energy Co., Ltd.

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Please write to us at [email protected]

Recent Developments of Alkaline Electrolyzer Stack Systems Market

Recent Market JVs and Acquisitions:

A considerable number of strategic alliances, including M&As, JVs, etc., have been performed over the past few years:

-

In Aug 2024, India's Advait Infratech Ltd signed a technology licensing deal with China's Guofu Hydrogen Energy Equipment. The tie-up provides Advait with access to Guofu's alkaline electrolyzer technology to allow local production and assembly of equipment for India's green hydrogen production. The production capacity is initially 300 MW/year, with future expansion to 1,000 MW/year.

-

In May 2024, Reliance Industries Ltd (RIL) entered into a technology licensing deal with Norway-based Nel Hydrogen Electrolyser, which is a subsidiary of Nel ASA. The deal grants RIL an exclusive license for Nel's alkaline electrolyzers in India and allows RIL to produce these electrolyzers for its international operations.

Recent Product Development:

Most recent developments concerning Alkaline electrolyzer stack systems have been around cost reduction to ensure commercial viability and tackle the issues of sustainability and environmental restrictions.

-

In October 2024, Greenzo Energy unveiled the "Un Wheel," a 1 MW alkaline electrolyzer stack designed to function reliably across diverse Indian climates, operating effectively in temperatures ranging from -20°C to 60°C. The system delivers hydrogen at 30 bar pressure, eliminating the need for additional compressors, and has a lifespan of 20 years.

-

In June 2024, Suzhou-based CPU Hydrogen Power Technology (CPUH2) developed a 1.1 MW containerized alkaline water electrolysis hydrogen production system. The system's hydrogen production is said to be 200 Nm3/h, or up to 428 kg/24hr, with a purity of up to 99.999%.

Report Features

This report provides market intelligence most comprehensively. The report structure has been kept so that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market. The following are the key features of the report:

-

Market structure: Overview, industry life cycle analysis, supply chain analysis.

-

Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

-

Market trend and forecast analysis.

-

Market segment trend and forecast.

-

Competitive landscape and dynamics: Market share, Product portfolio, New Product Launches, etc.

-

COVID-19 impact and its recovery curve

-

Attractive market segments and associated growth opportunities.

-

Emerging trends.

-

Strategic growth opportunities for the existing and new players.

-

Key success factors.

Market Segmentation

The global alkaline electrolyzer stack systems market is segmented into the following categories:

By Power-Supply Type

-

Renewable Energy

-

Grid

-

Other Power Supplies

By End-Use Type

-

Transportation

-

Chemicals

-

Refinery & Synfuels

-

Power

-

Iron & Steel

-

Other End-Uses

By Region

-

North America (Country Analysis: The USA, Canada, and Mexico)

-

Europe (Country Analysis: Germany, France, Austria, and Rest of Europe)

-

Asia-Pacific (Country Analysis: Japan, China, India, and Rest of Asia-Pacific)

-

Rest of the World (Country Analysis: Brazil, Saudi Arabia, and Others)

Research Methodology

This strategic assessment report from Stratview Research provides a comprehensive analysis that reflects today’s alkaline electrolyzer stack systems market realities and future market possibilities for the forecast period. The report segments and analyzes the market in the most detailed manner in order to provide a panoramic view of the market. The vital data/information provided in the report can play a crucial role for market participants and investors in identifying the low-hanging fruit available in the market and formulating growth strategies to expedite their growth process.

This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools. More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data. We conducted more than 15 detailed primary interviews with market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Report Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respected clients:

Company Profiling

Competitive Benchmarking

-

Benchmarking of key players on the following parameters: Product portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview Research offers custom research services across industries. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to [email protected]