Attractive Opportunities

Global Demand Analysis & Sales Opportunities in Electrolyzer MEA Market

-

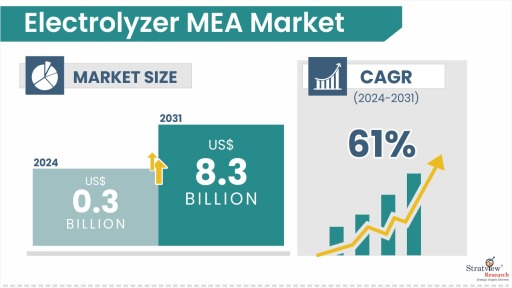

The annual demand for electrolyzer MEA was USD 0.3 billion in 2024 and is expected to reach USD 0.5 billion in 2025, up 39.3% than the value in 2024.

-

During the forecast period (2025-2031), the electrolyzer MEA market is expected to grow at a CAGR of 61.0%. The annual demand will reach USD 8.3 billion in 2031.

-

During 2025-2031, the electrolyzer MEA industry is expected to generate a cumulative sales opportunity of USD 21.1 billion.

Want to get a free sample? Register Here

High-Growth Market Segments:

-

Asia-Pacific region is expected to maintain its reign over the forecast period.

-

By electrolyzer type, Alkaline electrolyzers are expected to be the largest electrolyzer type for the global MEA market due to their maturity state and extensive use, owing to the high technological readiness level in the market.

-

By end-use type, Chemicals are anticipated to be the largest demand generator contributing to the growth of the electrolyzer MEA market. Transportation will also occupy a significant share of the market in the coming years.

Market Statistics

Have a look at the sales opportunities presented by the electrolyzer MEA market in terms of growth and market forecast.

|

Electrolyzer MEA Market Data & Statistics

|

|

|

Market Statistics

|

Value (in USD Billion)

|

Market Growth (%)

|

|

Annual Market Size in 2024

|

USD 0.3 billion

|

-

|

|

Annual Market Size in 2025

|

USD 0.5 billion

|

YoY Growth in 2025: 39.3%

|

|

Annual Market Size in 2031

|

USD 8.3 billion

|

CAGR 2025-2031: 61.0%

|

|

Cumulative Sales Opportunity during 2025-2031

|

USD 21.1 billion

|

-

|

Market Dynamics

Introduction:

The Membrane Electrode Assembly (MEA) is a critical component in all types of electrolyzers, facilitating the electrochemical reaction required for hydrogen production. While it is most commonly associated with Proton Exchange Membrane (PEM) electrolyzers, MEAs also play a vital role in Alkaline Electrolyzers, Solid Oxide Electrolyzers (SOEC), and Anion Exchange Membrane (AEM) electrolyzers, each with distinct designs and operating principles.

In PEM electrolyzers, the MEA consists of a proton-conducting membrane and catalyst layers (typically platinum or iridium), enabling efficient, high-purity hydrogen production. Operating in an acidic environment, these electrolyzers rely on noble metal catalysts for stability and performance.

In Alkaline Electrolyzers, the MEA is less pronounced since these systems use a liquid potassium hydroxide (KOH) electrolyte instead of a solid membrane. However, nickel-based electrodes and porous separators perform similar functions by facilitating ion transport while preventing gas crossover.

Solid Oxide Electrolyzers (SOEC) incorporate ceramic-based MEAs, operating at high temperatures (700–1000°C) to achieve superior efficiency due to enhanced reaction kinetics. However, they require robust materials to withstand extreme conditions.

Anion Exchange Membrane (AEM) electrolyzers feature an MEA similar to PEM systems but use an anion-conducting polymer membrane, which allows hydroxide ions (OH?) to migrate. This setup enables the use of non-precious metal catalysts, making them a more cost-effective alternative.

With advancements in materials science and engineering, MEAs across different electrolyzer types are being optimized for greater efficiency, durability, and affordability, positioning them at the forefront of green hydrogen technology.

Market Drivers:

The membrane electrode assembly (MEA) market for electrolyzers is experiencing rapid growth, driven by several key factors.

-

A primary catalyst is the rising demand for green hydrogen as industries and governments worldwide push toward carbon neutrality. MEAs are fundamental to hydrogen production in Proton Exchange Membrane (PEM), Anion Exchange Membrane (AEM), and Solid Oxide Electrolyzers (SOEC), making them essential for the advancement of the hydrogen economy.

-

Another major driver is advancements in materials science, enabling the development of more efficient, durable, and cost-effective MEAs. Innovations such as non-precious metal catalysts, enhanced membrane conductivity, and increased longevity are reducing reliance on expensive platinum-group metals, lowering costs, and accelerating market adoption.

-

Additionally, government policies, subsidies, and investments in green hydrogen projects are driving substantial growth in electrolyzer technologies, directly boosting MEA demand. As hydrogen applications expand across mobility, industrial processes, and energy storage, the need for high-performance MEAs will continue to rise, reinforcing their role in the future of sustainable energy.

Market Challenges:

-

The membrane electrode assembly (MEA) market for electrolyzers faces challenges due to the high cost of precious metal catalysts like platinum and iridium, limiting affordability and scalability.

-

MEAs also suffer from durability issues, degrading under extreme conditions, which reduces efficiency and increases maintenance costs.

-

Additionally, scalability remains a hurdle, as complex manufacturing processes make mass production difficult. MEAs compete with lower-cost alkaline electrolyzers, which do not require expensive components.

Segment Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High-Growth Opportunity

|

|

Electrolyzer-Type Analysis

|

PEM Electrolyzer, Alkaline Electrolyzer, SOEC, AEM Electrolyzer, and Other Electrolyzers.

|

Alkaline electrolyzers are expected to be the largest electrolyzer type for the global MEA market due to their maturity state and extensive use, owing to the high technological readiness level in the market.

|

|

End-Use Type Analysis

|

Transportation, Chemicals, Refinery & Synfuels, Power, Iron & Steel, and Other End-Uses.

|

Chemicals are anticipated to be the largest demand generator contributing to the growth of the electrolyzer MEA market. The rise of electrolyzers in chemical synthesis will boost the growth of the electrolyzer MEA market. Transportation will also occupy a significant share of the market in the coming years.

|

|

Region Analysis

|

North America, Europe, Asia-Pacific, and The Rest of the World

|

The Asia-Pacific region is expected to maintain its reign over the forecast period.

|

Electrolyzer Insights

“Alkaline electrolyzers are projected to dominate the electrolyzer MEA market, thanks to their advanced state of development and widespread adoption, driven by their high technological readiness and proven reliability.”

-

The electrolyzer MEA Market is segmented into PEM electrolyzer, Alkaline electrolyzer, SOEC, AEM electrolyzers, and other electrolyzers by electrolyzer type.

-

Alkaline electrolyzers are expected to take the lead in the global MEA market due to their technological readiness, affordability, and extensive industrial applications. With a high Technology Readiness Level (TRL), alkaline electrolyzers have found vast commercial applications for large-scale hydrogen production, particularly in ammonia manufacturing, refineries, and steel-making processes. Their low-cost materials, scalability, and proven reliability make them the preferred technology for bulk hydrogen production.

-

Although PEM electrolyzers are experiencing rapid growth due to their compact size and efficiency, they remain more expensive due to the use of platinum-group metals. Even with increasing demand for PEM electrolyzers in hydrogen mobility and grid applications, alkaline electrolyzers will continue to lead the market because of their cost-effectiveness and compatibility with renewable energy sources.

-

Additionally, AEM electrolyzers are emerging as a promising technology, offering a balance between alkaline and PEM electrolyzers. AEM systems are designed to combine the cost benefits of alkaline technology with the efficiency of PEM without relying on precious metals. As AEM technology advances, it is expected to capture a growing market share, but alkaline electrolyzers will remain dominant due to their large-scale industrial use and economic advantages.

End-Use Insights

“Chemicals are anticipated to be the largest end-use contributing to the growth of the electrolyzer MEA market. The rise of electrolyzers in chemical synthesis will boost the growth of the electrolyzer MEA market. Transportation will also occupy a significant share of the market in the coming years.”

-

The market is segmented into transportation, chemicals, refinery & synfuels, power, iron & steel, and other end-uses by end-use type.

-

The chemical industry is expected to be the leading end-use application driving the growth of the MEA market as electrolyzers gain wider adoption for large-scale hydrogen production. Hydrogen is a crucial feedstock for ammonia and methanol production, and as industries transition to green hydrogen, electrolyzers are becoming essential in replacing fossil fuel-based hydrogen sources. MEAs, particularly in PEM and AEM electrolyzers, enhance efficiency and hydrogen purity, making them vital for chemical synthesis.

-

Beyond the chemical industry, transportation will also play a key role in the MEA market expansion. Hydrogen fuel cell vehicles, including cars, trucks, buses, and trains, rely on PEM electrolyzers for high-purity hydrogen production. As investments in hydrogen refueling infrastructure and zero-emission mobility initiatives increase, demand for MEAs in transportation will continue to grow.

Regional Analysis

“The Asia-Pacific region is expected to maintain its reign over the forecast period.”

-

The electrolyzer MEA market is segmented into North America, Europe, Asia-Pacific, and the rest of the world by region type.

-

The Asia-Pacific region will be a key driver of the electrolyzer MEA market for electrolyzers, supported by rapid industrialization, strong government policies, and significant investments in green hydrogen infrastructure. Countries like China, Japan, South Korea, and India are accelerating electrolyzer production to meet the rising demand in industries such as chemicals, refining, and transportation.

-

China dominates in large-scale, cost-effective electrolyzer manufacturing, lowering overall system costs and increasing MEA adoption. Meanwhile, Japan and South Korea are heavily investing in hydrogen fuel cell vehicles and refueling networks, boosting demand for high-performance MEAs, particularly in PEM electrolyzers.

-

Additionally, government incentives, subsidies, and carbon neutrality goals are driving advancements in electrolyzer efficiency and affordability. With continued policy support and technological progress, Asia-Pacific is expected to remain the global leader in the electrolyzer MEA market for electrolyzers throughout the forecast period.

Want to get a free sample? Register Here

Competitive Landscape

The market is consolidated, with major players holding a significant portion of the market. Most of the major players compete in some of the governing factors, including price, product offerings, regional presence, etc. The following are the key players in the electrolyzer MEA market.

Here is the list of the Top Players (Based on Dominance)

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Please write to us at [email protected]

Recent Developments

Recent Market JVs and Acquisitions:

The recent mergers and acquisitions in the market are driven by the need for advanced materials, the supply chain strengthening, and reducing production costs.

-

In February 2024, Bekaert and Toshiba Energy Systems and Solutions Corporation entered into a global partnership involving a strategic cooperation agreement and a manufacturing technology license for MEAs. This collaboration aims to accelerate green hydrogen production by combining Bekaert's expertise in Porous Transport Layers (PTL) with Toshiba's innovative iridium-saving MEA technology, which reduces iridium usage by 90%, facilitating a more stable supply of MEAs.

-

In May 2021, Cummins Inc. and Air Liquide announced the formation of a joint venture to develop and manufacture electrolyzers in Europe. This collaboration aims to accelerate the production of green hydrogen, leveraging Cummins' expertise in MEA technology and Air Liquide's experience in gas handling and infrastructure

Recent Product Development:

-

In September 2024, Hygreen Energy launched its first Anion Exchange Membrane (AEM) electrolyzer system, expanding its product portfolio beyond alkaline and PEM electrolyzers. The new AEM system offers a plug-and-play solution with customizable capacities up to 100 Nm³/hr (500 kW) of hydrogen production and operates across a load range of 10% to 120%, enhancing flexibility and efficiency in hydrogen generation.

Report Features

This report provides market intelligence most comprehensively. The report structure has been kept so that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market.

The following are the key features of the report:

-

Market structure: Overview, industry life cycle analysis, supply chain analysis.

-

Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

-

Market trend and forecast analysis.

-

Market segment trend and forecast.

-

Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

-

COVID-19 impact and its recovery curve.

-

Attractive market segments and associated growth opportunities.

-

Emerging trends.

-

Strategic growth opportunities for the existing and new players.

-

Key success factors.

|

Market Study Period

|

2019-2031

|

|

Base Year

|

2024

|

|

Forecast Period

|

2025-2031

|

|

Trend Period

|

2019-2023

|

|

Number of Tables & Figures

|

>100

|

|

Number of Segments Analysed

|

3 (Electrolyzer Type, End-Use Type, and Region)

|

|

Number of Regions Analysed

|

4 (North America, Europe, Asia-Pacific, Rest of the World)

|

|

Countries Analysed

|

15 (The USA, Canada, Mexico, Germany, France, Italy, The UK, China, Japan, India, Brazil, Saudi Arabia, Rest of Europe, Rest of APAC, and Rest of the World)

|

|

Free Customization Offered

|

10%

|

|

After Sales Support

|

Unlimited

|

|

Report Presentation

|

Complimentary

|

|

Market Dataset

|

Complimentary

|

|

Further Deep Dive & Consulting Services

|

10% Discount

|

Market Segmentation

The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The global electrolyzer MEA market is segmented into the following categories:

Electrolyzer MEA Market, by Electrolyzer Type

-

PEM Electrolyzer

-

Alkaline Electrolyzer

-

SOEC

-

AEM Electrolyzer

-

Other Electrolyzers

Electrolyzer MEA Market, by End-Use Type

-

Transportation

-

Chemicals

-

Refinery & Synfuels

-

Power

-

Iron & Steel

-

Other End-Uses

Electrolyzer MEA Market, by Region

-

North America (Country Analysis: The USA, Canada, and Mexico)

-

Europe (Country Analysis: Germany, France, Austria, and Rest of Europe)

-

Asia-Pacific (Country Analysis: Japan, China, India, and Rest of Asia-Pacific)

-

Rest of the World (Country Analysis: Brazil, Argentina, and Others)

Research Methodology

-

This strategic assessment report from Stratview Research provides a comprehensive analysis that reflects today’s electrolyzer MEA market realities and future market possibilities for the forecast period

-

The report segments and analyzes the market in the most detailed manner to provide a panoramic view of the market.

-

The vital data/information provided in the report can play a crucial role for market participants and investors in identifying the low-hanging fruits available in the market and formulating growth strategies to expedite their growth process.

-

This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools.

-

More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data.

-

We conducted more than 15 detailed primary interviews with market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respected clients:

Company Profiling

Competitive Benchmarking

-

Benchmarking of key players on the following parameters: Product portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview Research offers custom research services across industries. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to [email protected]