Attractive Opportunities

Global Demand Analysis & Sales Opportunities in Electrolyzer Porous Transport Layer Market

-

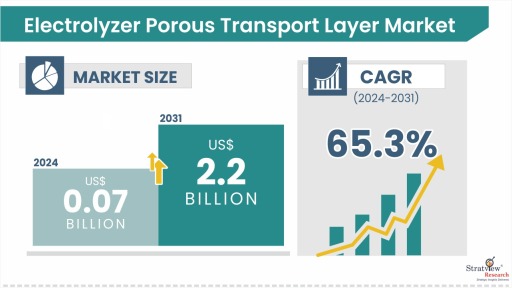

The annual demand for electrolyzer porous transport layer was USD 0.07 billion in 2024 and is expected to reach USD 0.1 billion in 2025, up 43.3% than the value in 2024.

-

During the forecast period (2025-2031), the electrolyzer porous transport layer market is expected to grow at a CAGR of 65.3%. The annual demand will reach USD 2.2 billion in 2031.

-

During 2025-2031, the electrolyzer porous transport layer industry is expected to generate a cumulative sales opportunity of USD 5.5 billion.

Want to get a free sample? Register Here

High-Growth Market Segments:

-

Asia-Pacific region is expected to maintain its reign over the forecast period.

-

By electrolyzer type, PEM electrolyzer porous transport layer currently dominates the market and is forecasted to reign during the study period.

-

By end-use type, Transportation is expected to be the leading end-use, contributing to the growth of the porous transport layer with the growing adoption of hydrogen in the mobility driving market expansion.

Market Statistics

Have a look at the sales opportunities presented by the electrolyzer porous transport layer market in terms of growth and market forecast.

|

Electrolyzer Porous Transport Layer Market Data & Statistics

|

|

|

Market Statistics

|

Value (in USD Billion)

|

Market Growth (%)

|

|

Annual Market Size in 2024

|

USD 0.07 billion

|

-

|

|

Annual Market Size in 2025

|

USD 0.1 billion

|

YoY Growth in 2025: 43.3%

|

|

Annual Market Size in 2031

|

USD 2.2 billion

|

CAGR 2025-2031: 65.3%

|

|

Cumulative Sales Opportunity during 2025-2031

|

USD 5.5 billion

|

-

|

Market Dynamics

Introduction:

The porous transport layer (PTL) is a vital component in electrolyzers, acting as an intermediary between the catalyst layer and the current collector. Typically made from conductive materials like carbon paper, carbon cloth, or other similar substrates, the porous transport layer (PTL) plays a crucial role in facilitating the transport of reactants and products to and from the catalyst layer while also conducting electrons to the external circuit. Its highly porous structure is essential for enabling efficient gas and liquid flow, which significantly impacts the overall performance of the electrolyzer. The porous transport layer serves several important functions in an electrolyzer. It ensures uniform distribution of reactants, such as water, and products, such as hydrogen and oxygen, which prevents localized flooding or dehydration of the catalyst layer. By optimizing the flow of these substances, the porous transport layer helps the catalyst layer operate at its maximum efficiency. Additionally, it assists in water management and heat dissipation, both of which are crucial for the stability and longevity of the electrolyzer.

Recent advancements in porous transport layer materials and design have focused on improving conductivity, porosity, and corrosion resistance. Researchers are exploring innovative composite materials, including carbon-based nanomaterials and metal-organic frameworks (MOFs), to enhance porous transport layer performance. Moreover, developments in 3D printing and new manufacturing techniques are enabling the production of more efficient and durable porous transport layers, enhancing electrolyzer efficiency while reducing production costs.

Market Drivers:

-

The growth of the electrolyzer porous transport layer (PTL) market is driven by increasing demand for clean energy solutions and advancements in electrolyzer technology. The global push for renewable energy, especially green hydrogen production, is the primary driver as industries aim to decarbonize and reduce reliance on fossil fuels.

-

High-performance porous transport layers are crucial for enhancing electrolyzer efficiency, ensuring optimal gas and liquid flow, and improving overall hydrogen production performance. Advancements in electrolyzer design and manufacturing are further contributing to the rising demand for efficient PTLs.

-

Innovations in materials, such as carbon-based composites and metal-organic frameworks (MOFs), are enhancing porous transport layer conductivity, porosity, and corrosion resistance, making them increasingly integral to electrolyzer systems.

-

The growing use of electrolyzers in industries like energy storage, transportation, and industrial applications, along with supportive government policies promoting clean energy and hydrogen infrastructure, is creating favorable conditions for large-scale electrolyzer deployment and driving market expansion.

Market Challenges:

-

The porous transport layer (PTL) market for electrolyzers faces several challenges, including high material costs due to the use of advanced materials like carbon composites and metal-organic frameworks (MOFs), which limit cost-effectiveness, especially for large-scale hydrogen production.

-

The complex manufacturing processes are resource-intensive and hinder scalability. Porous transport layers also face issues with long-term durability and degradation under harsh conditions.

-

Additionally, the lack of standardized testing protocols for porous transport layers complicates material evaluation and slows down technological progress.

Segment Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High-Growth Opportunity

|

|

Electrolyzer-Type Analysis

|

PEM Electrolyzer, Alkaline Electrolyzer, AEM Electrolyzer, and Other Electrolyzers

|

The PEM electrolyzer porous transport layer currently dominates the market and is forecasted to reign during the study period.

|

|

End-Use Type Analysis

|

Transportation, Chemicals, Refinery & Synfuels, Power, Iron & Steel, and Other End-Uses

|

Transportation is expected to be the leading end-use, contributing to the growth of the porous transport layer with the growing adoption of hydrogen in the mobility driving market expansion.

|

|

Region Analysis

|

North America, Europe, Asia-Pacific, and The Rest of the World

|

The Asia-Pacific region is expected to maintain its reign over the forecast period.

|

Electrolyzer Insights

“The porous transport layer of PEM electrolyzers currently leads the market and is set to maintain its stronghold in the coming years.”

-

The electrolyzer porous transport layer market is segmented into PEM electrolyzer, Alkaline electrolyzer, AEM electrolyzer, and other electrolyzers.

-

The electrolyzer porous transport layer (PTL) market is currently dominated by PEM electrolyzers and is expected to maintain this lead throughout the forecast period. This is primarily due to the widespread adoption of proton exchange membrane (PEM) electrolyzers, which rely on advanced porous transport layers for enhanced performance. As global demand for green hydrogen rises, industries prefer PEM electrolyzers over alkaline alternatives due to their higher efficiency, compact design, and faster response time.

-

The growth of the PEM electrolyzer market is directly tied to the expansion of the porous transport layer market, as porous transport layers play a vital role in ensuring uniform gas and water distribution, reducing electrical resistance, and improving system durability. Technological advancements, such as titanium-based porous transport layers, are driving further innovation by increasing efficiency and lifespan.

-

Government policies and investments in clean energy solutions are accelerating the demand for PEM electrolyzers, thereby boosting the porous transport layer market. With the global shift toward decarbonization, the porous transport layer market is set to expand further, solidifying its position as a crucial component in the growing PEM electrolyzer industry.

End-Use Insights

“Transportation is set to emerge as the top end-use industry, fueling the growth of the porous transport layer, as the rising adoption of hydrogen-powered mobility accelerates market expansion.”

-

The market is segmented into transportation, chemicals, refinery & synfuels, power, iron & steel, and other end-uses.

-

The transportation industry is projected to be the largest end-use application driving the growth of the porous transport layer (PTL) market, primarily due to its expanding role in hydrogen-powered mobility. As industries and governments worldwide intensify efforts to reduce carbon emissions, hydrogen fuel cell vehicles (FCEVs) emerge as a viable alternative to internal combustion engines and battery-electric vehicles. PEM electrolyzers play a crucial role in hydrogen production, and their efficiency depends on advanced porous transport layers that optimize gas and water distribution, minimize electrical resistance, and enhance system durability.

-

With the rapid expansion of hydrogen refueling infrastructure and rising investments in fuel cell-powered transportation, including trucks, buses, trains, and even aircraft, the demand for high-performance electrolyzers and porous transport layers is increasing significantly. Additionally, government policies and incentives promoting clean transportation are accelerating the shift toward hydrogen-powered mobility, further driving the porous transport layer market expansion.

-

As hydrogen adoption grows across the automotive, maritime, and aerospace industries, porous transport layers will remain an essential component, ensuring efficient electrolyzer operation and solidifying their dominance in the transport-driven hydrogen economy.

Regional Insights

“The Asia-Pacific region is poised to retain its leadership throughout the forecast period, continuing to drive momentum and shape market trends.”

-

The Asia-Pacific region is set to remain the leading driver of the electrolyzer porous transport layer market, driven by its rapid adoption of electrolyzer technology, supportive government policies, and expanding hydrogen infrastructure.

-

China, Japan, and South Korea are making significant investments in renewable energy and hydrogen infrastructure projects, driving the demand for porous transport layers. China, the world’s largest electrolyzer market, is rapidly expanding hydrogen production and increasing its fleet of fuel cell trucks and buses.

-

Meanwhile, South Korea’s hydrogen economy vision and Japan’s Hydrogen Society Roadmap continue to support market growth. With ongoing technological advancements and rising production capacity, the Asia-Pacific region is expected to maintain its leading position in the electrolyzer porous transport layer market for the foreseeable future.

Want to get a free sample? Register Here

Competitive Landscape

The market is consolidated, with major players holding a significant portion of the market. Most of the major players compete in some of the governing factors, including price, product offerings, regional presence, etc. The following are the key players in the electrolyzer porous transport layer market. Here is the list of the Top Players (Based on Dominance)

-

Freudenberg Performance Materials

-

Bekaert

-

Toray Industries Inc.

-

SGL Carbon SE

-

Mitsubishi Chemical Corporation

-

Avcarb Material Solutions

-

CAPLINQ Corporation

-

Mott Corporation

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Please write to us at [email protected]

Recent Developments

Recent Market JVs and Acquisitions:

The recent mergers and acquisitions in the market are driven by the need for advanced materials, the supply chain strengthening, and reducing production costs.

-

In 2024, Toshiba and Bekaert entered into a global partnership to accelerate green hydrogen production through advanced MEA (Membrane Electrode Assembly) technology for PEM electrolyzers. Under the agreement, Bekaert’s leading expertise in porous transport layer will be coupled with Toshiba’s innovative iridium-saving technology.

Recent Product Development:

Report Features

This report provides market intelligence most comprehensively. The report structure has been kept so that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market.

The following are the key features of the report:

-

Market structure: Overview, industry life cycle analysis, supply chain analysis.

-

Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

-

Market trend and forecast analysis.

-

Market segment trend and forecast.

-

Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

-

COVID-19 impact and its recovery curve.

-

Attractive market segments and associated growth opportunities.

-

Emerging trends.

-

Strategic growth opportunities for the existing and new players.

-

Key success factors.

|

Market Study Period

|

2019-2031

|

|

Base Year

|

2024

|

|

Forecast Period

|

2025-2031

|

|

Trend Period

|

2019-2023

|

|

Number of Tables & Figures

|

>100

|

|

Number of Segments Analysed

|

3 (Electrolyzer Type, End-Use Type, and Region)

|

|

Number of Regions Analysed

|

4 (North America, Europe, Asia-Pacific, Rest of the World)

|

|

Countries Analysed

|

15 (The USA, Canada, Mexico, Germany, France, Italy, The UK, China, Japan, India, Brazil, Saudi Arabia, Rest of Europe, Rest of APAC, and Rest of the World)

|

|

Free Customization Offered

|

10%

|

|

After Sales Support

|

Unlimited

|

|

Report Presentation

|

Complimentary

|

|

Market Dataset

|

Complimentary

|

|

Further Deep Dive & Consulting Services

|

10% Discount

|

Market Segmentation

The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The global electrolyzer porous transport layer market is segmented into the following categories:

Electrolyzer Porous Transport Layer Market, by Electrolyzer Type

-

PEM Electrolyzer

-

Alkaline Electrolyzer

-

AEM Electrolyzer

-

Other Electrolyzers

Electrolyzer Porous Transport Layer Market, by End-Use Type

-

Transportation

-

Chemicals

-

Refinery & Synfuels

-

Power

-

Iron & Steel

-

Other End-Uses

Electrolyzer Porous Transport Layer Market, by Region

-

North America (Country Analysis: The USA, Canada, and Mexico)

-

Europe (Country Analysis: Germany, France, Austria, and Rest of Europe)

-

Asia-Pacific (Country Analysis: Japan, China, India, and Rest of Asia-Pacific)

-

Rest of the World (Country Analysis: Brazil, Saudi Arabia, and Others)

Research Methodology

-

This strategic assessment report from Stratview Research provides a comprehensive analysis that reflects today’s electrolyzer porous transport layer market realities and future market possibilities for the forecast period

-

The report segments and analyzes the market in the most detailed manner to provide a panoramic view of the market.

-

The vital data/information provided in the report can play a crucial role for market participants and investors in identifying the low-hanging fruits available in the market and formulating growth strategies to expedite their growth process.

-

This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools.

-

More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data.

-

We conducted more than 15 detailed primary interviews with market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respected clients:

Company Profiling

Competitive Benchmarking

-

Benchmarking of key players on the following parameters: Product portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview Research offers custom research services across industries. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to [email protected]