Attractive Opportunities

Global Demand Analysis & Sales Opportunities in Forged Composite Market

-

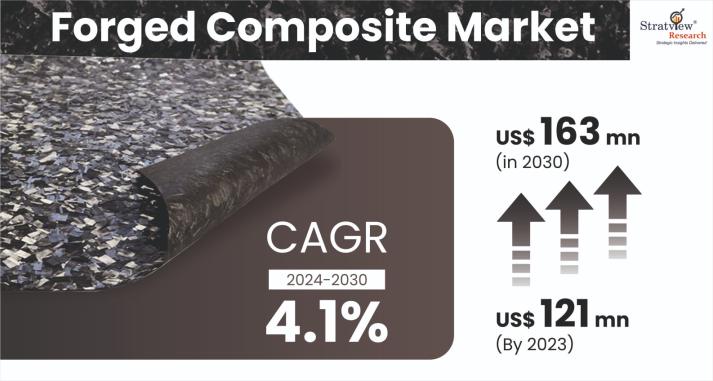

The annual demand for forged composite was USD 128 million in 2024 and is expected to reach USD 134 million in 2025, up 4.9% than the value in 2024.

-

During the forecast period (2025-2030), the forged composite market is expected to grow at a CAGR of 4.0%. The annual demand will reach USD 163 million in 2030.

-

During 2025-2030, the forged composite industry is expected to generate a cumulative sales opportunity of USD 891 million.

Wish to get a free sample? Register Here

High-Growth Market Segments:

-

Europe is expected to remain the largest market for forged composite during the forecast period, whereas Asia-Pacific is the fastest-growing region in the market.

-

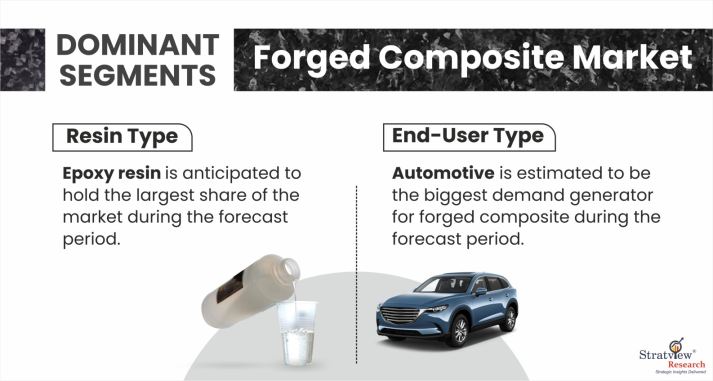

By resin type, Epoxy resin is anticipated to hold the largest share of the market during the forecast period.

-

By end-user type, Automotive is estimated to be the biggest demand generator for forged composite during the forecast period.

Market Statistics

Have a look at the sales opportunities presented by the forged composite market in terms of growth and market forecast.

|

Forged Composite Market Data & Statistics

|

|

|

Market Statistics

|

Value (in USD Million)

|

Market Growth (%)

|

|

Annual Market Size in 2023

|

USD 121 million

|

-

|

|

Annual Market Size in 2024

|

USD 128 million

|

YoY Growth in 2024: 5.4%

|

|

Annual Market Size in 2025

|

USD 134 million

|

YoY Growth in 2025: 4.9%

|

|

Annual Market Size in 2030

|

USD 163 million

|

CAGR 2025-2030: 4.0%

|

|

Cumulative Sales Opportunity during 2025-2030

|

USD 891 million

|

-

|

|

Top 10 Countries’ Market Share in 2024

|

USD 102 million +

|

> 80%

|

|

Top 10 Company’s Market Share in 2024

|

USD 64 million to USD 90 million

|

50% - 70%

|

Market Dynamics

Introduction:

Forged composite is a unique material that differs significantly from traditional composites. Unlike traditional composites, which use continuous fibers woven into a fabric, forged composite is made from short, chopped fibers mixed with resin and then molded into shape under high pressure and heat. The process of making forged composite is similar to metal forging. First, pieces of chopped fibers are spread across a mold. Then, the resin is impregnated into the fibers, and the mold is compressed using a power press.

The fiber pieces are positioned in multi-directional orientations to provide 3D strength. Next, the mold is heated to stimulate chemical reactions, causing the resin to cure and harden. After the curing process is complete, the molded component is removed from the mold and undergoes finishing processes such as chamfering, trimming, surface treatment, and polishing, depending on the application. This process results in a material with a random, marbled appearance, unlike the regular weave pattern of traditional fiber.

Sports cars utilize a range of carbon fiber composites, including forged composites. Examples include monocoque chassis, suspension, and seat supports, which are primarily structural components. Lamborghini concept cars have frequently incorporated such materials. The aerospace industry has long benefited from a wide range of carbon fiber products. Being light and highly moldable, they also find use in sporting equipment like golf and tennis.

Furthermore, due to its refined aesthetics, non-corrosive nature, skin-safe properties, low coefficient of thermal expansion, high dimensional accuracy, and water-proof nature, forged composite is being used in various lifestyle applications such as luxury watches and high-end mobile phone components and related accessories.

Segments Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High Growth Opportunity

|

|

Resin-Type Analysis

|

Epoxy Composite, Vinyl Ester Composite, Polyurethane Composite, BMI Composite, Phenolic Composite, and Other Composites.

|

Epoxy resin is anticipated to hold the largest share of the market during the forecast period.

|

|

End-User-Type Analysis

|

Automotive, Sports, Consumer Goods, Industrial, and Aerospace.

|

Automotive is estimated to be the biggest demand generator for forged composite during the forecast period.

|

|

Regional Analysis

|

North America, Europe, Asia Pacific, and The Rest of the World.

|

Europe is expected to remain the largest market for forged composite during the forecast period, whereas Asia-Pacific is the fastest-growing region in the market.

|

By Resin Type

“Epoxy resin is expected to hold the largest share of the market during the forecast period”.

-

The market is segmented into epoxy composite, vinyl ester composite, polyurethane composite, bismaleimide (BMI) composite, phenolic composite, and other composites.

-

Epoxy resin is chemically balanced from a mechanical viewpoint since it exhibits high strength, stiffness, and bonding strength. It therefore becomes a material that can be applied universally in various applications in the forged composite market. For instance, epoxy resin strengthens the carbon fiber layers to make forged composite parts for automobiles, bicycles, and sporting equipment.

-

Epoxy resins have strong adhesive properties, ensuring a secure bond with carbon fibers. This enhances the overall integrity and performance of the forged composite.

-

Epoxy resins have a manageable curing process, which can be tailored to suit different manufacturing techniques, such as compression molding used in forged composites.

Want to get more details about the segmentations? Register Here

By End-User Type

“Automotive is anticipated to be the dominant end-user type of the market during the forecast period”.

-

The market is segmented into automotive, sports, consumer goods, industrial, and aerospace.

-

The manufacturing process for forged composites allows for the creation of complex shapes and intricate designs that are difficult to achieve with traditional materials. In addition to that, the unique appearance of forged composites can be leveraged in both visible parts and interior designs, adding to the aesthetic value of the vehicle.

-

High-performance and luxury vehicle segments often lead the way in adopting advanced materials, and forged composites provide the necessary performance and aesthetic characteristics.

-

Forged composites offer a high strength-to-weight ratio, allowing for enhanced vehicle performance without compromising safety. The durability and rigidity of forged composites make them ideal for structural parts, improving overall vehicle dynamics.

-

The compression molding process used for forged composites is faster and more efficient than traditional methods, reducing production time and cost.

Regional Analysis

“Europe is likely to be the largest market during the forecast period”.

-

Europe took the largest share of the said market for several reasons. The region’s automotive and aerospace engineering industries have a record of innovation and experience in implementing forged composite products. This provided forged composite development and adoption with a solid base and knowledgeable workforce in Europe, meaning that this region became one of the leaders in this sphere. Secondly, forcible emissions regulation norms in Europe make using forged composites inevitable to reduce overall emissions, driving the overall market growth.

-

Europe has a strong presence in the luxury automotive segment, which has been at the forefront of adopting advanced materials like forged composites for performance and aesthetic enhancements.

-

Economic growth in countries like China and India has led to an expanding middle class with increased disposable income. This demographic drives demand for premium sports equipment and consumer goods incorporating advanced materials like forged composites.

-

There is a growing interest in sports and fitness activities across Asia-Pacific, leading to a higher demand for high-quality sports equipment such as golf clubs, tennis rackets, and bicycles, which benefit from the lightweight and strong properties of forged composites.

Want to know which region offers the best growth opportunities? Register Here

Competitive Landscape

The market is partially fragmented across the region. Most of the major players compete in some of the governing factors including price, service offerings, regional presence, etc. The following are the key players in the Forged Composite Market:

Here is the list of the Top Players (Based on Dominance)

-

Callaway Golf

-

Forged Carbon (Tecalemit Group)

-

Mansory Design & Holding GmbH

-

Action Composites

-

Innovative Composite Engineering Inc.

-

Real Carbon Inc.

-

Bulgari

-

Modern Composites Ltd.

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Write to us at [email protected]

Recent Market JVs and Acquisitions:

A huge number of strategic alliances including M&As, JVs, etc. have been performed over the past few years:

-

In July 2024, AWA Forged Composites™ was shifted to Mitsubishi Chemical Corporation of Japan to enhance the company’s ability in the highly specialized forged composite for industrial use.

-

In June 2024, Simply Carbon Fiber was acquired by ForgeLux based on the simulation done in this thesis. This acquisition seeks to complement its current line of products in luxury carbon fiber accessories for automobiles, specifically the forged products offered by ForgeLux.

-

In June 2024, MANSORY partnered with Pagani Automobili to produce forged carbon fiber parts for premium automobiles as well as for car designs to optimize the weight of bodies and the design factor.

-

In mid-2024, Creux Automatic teamed up with Roger Dubuis to integrate forged carbon parts into luxury watches.

Recent Product Development:

-

In February 2024, MANSORY unveiled new customization options for luxury vehicles, featuring extensive use of forged carbon fiber in exterior and interior components. This development focuses on aesthetics and performance enhancements for high-end vehicles.

Report Features

This report provides market intelligence most comprehensively. The report structure has been kept so that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market.

The following are the key features of the report:

-

Market structure: Overview, industry life cycle analysis, supply chain analysis.

-

Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

-

Market trend and forecast analysis.

-

Market segment trend and forecast.

-

Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

-

COVID-19 impact and its recovery curve.

-

Attractive market segments and associated growth opportunities.

-

Emerging trends.

-

Strategic growth opportunities for the existing and new players.

-

Key success factors.

|

Market Study Period

|

2019-2030

|

|

Base Year

|

2024

|

|

Forecast Period

|

2025-2030

|

|

Trend Period

|

2019-2023

|

|

Number of Tables & Figures

|

>100

|

|

Number of Segments Analysed

|

3 (Resin Type, End-User Type, and Region)

|

|

Number of Regions Analysed

|

4 (North America, Europe, Asia-Pacific, Rest of the World)

|

|

Countries Analysed

|

15 (The USA, Canada, Mexico, Germany, France, Italy, The UK, China, Japan, India, Brazil, Saudi Arabia, Rest of Europe, Rest of APAC, and Rest of the World)

|

|

Free Customization Offered

|

10%

|

|

After Sales Support

|

Unlimited

|

|

Report Presentation

|

Complimentary

|

|

Market Dataset

|

Complimentary

|

|

Further Deep Dive & Consulting Services

|

10% Discount

|

Market Segmentation

The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The global forged composite market is segmented into the following categories.

Forged Composite Market, by Resin Type

-

Epoxy Composite

-

Vinyl Ester Composite

-

Polyurethane Composite

-

BMI Composite

-

Phenolic Composite

-

Other Composites.

Forged Composite Market, by End-User Type

-

Automotive

-

Sports

-

Consumer Goods

-

Industrial

-

Aerospace

Forged Composite Market, by Region

-

North America (Country Analysis: The USA and Rest of North America)

-

Europe (Country Analysis: Turkey, Switzerland, Ukraine, and Rest of Europe)

-

Asia-Pacific (Country Analysis: Malaysia, China, South Korea, Indonesia, and Rest of Asia-Pacific)

-

Rest of the World (Country Analysis: Brazil, Saudi Arabia, and Others)

Research Methodology

-

This strategic assessment report from Stratview Research provides a comprehensive analysis that reflects today’s forged composite market realities and future market possibilities for the forecast period.

-

The report segments and analyzes the market in the most detailed manner in order to provide a panoramic view of the market.

-

The vital data/information provided in the report can play a crucial role for market participants as well as investors in the identification of the low-hanging fruits available in the market as well as to formulate growth strategies to expedite their growth process.

-

This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools.

-

More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data.

-

We conducted more than 15 detailed primary interviews with market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respectable clients:

Company Profiling

Competitive Benchmarking

-

Benchmarking of key players on the following parameters: Service portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview Research offers custom research services across sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to [email protected]