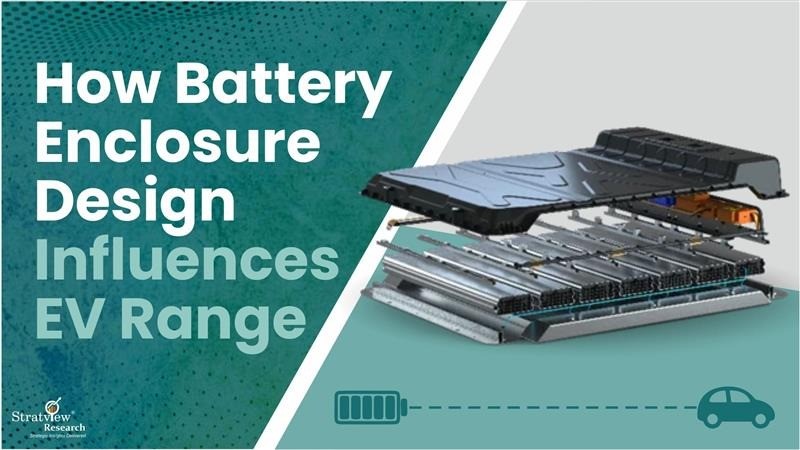

When electric vehicle range is discussed, attention almost always shifts toward battery chemistry, energy density, or motor efficiency. Yet, an equally important element often stays in the background, the structure that holds the entire battery system together. Battery enclosures may appear passive, but their design has a direct impact on how far an electric vehicle can travel on a single charge.

Even before energy is delivered to the motor, battery enclosure design influences range outcomes. Beyond protecting cells from mechanical and environmental stress, it determines how much non-functional mass the vehicle carries, how heat is controlled, and how efficiently the battery integrates into the vehicle structure. These factors collectively influence usable range, even if they remain largely invisible to the end user.

Why Battery Enclosure Weight Matters for EV Range

The influence of battery enclosures becomes most apparent through weight. A typical battery pack can weigh around 500 kg, with roughly 100 kg coming from enclosure materials alone, depending on vehicle size and battery capacity. This makes the enclosure one of the largest contributors to non-energy-storing mass in an electric vehicle.

Vehicle mass has a well-established relationship with energy consumption, particularly in urban and mixed driving cycles. According to the U.S. Environmental Protection Agency (EPA), reducing vehicle weight by about 100 pounds can improve efficiency by 1–2%. The same principle applies to electric vehicles, where every kilogram removed from the battery enclosure reduces energy demand during acceleration and stop-start driving, translating into measurable real-world range gains.

Lightweighting, Where Every Kilogram Counts

Material selection is therefore a critical design decision. Aluminium has become the preferred material for EV battery enclosures because it is approximately 40% lighter than steel while still offering sufficient structural strength and corrosion resistance. Today, around 80% of battery pack enclosures are made from aluminium, with most of the remainder constructed from steel.

Even so, metallic enclosures remain heavy. An empty metallic battery enclosure can add 110–160 kilograms to a vehicle’s mass, making it one of the heaviest structural components in the EV system. From a range standpoint, this mass does not contribute to energy storage, yet it must be moved every time the vehicle accelerates, increasing energy consumption and reducing efficiency.

Thermal Efficiency and Real-World EV Range

Range loss in electric vehicles often occurs not because battery capacity is insufficient, but because the battery operates outside its optimal temperature range. Lithium-ion batteries perform most efficiently between 20°C and 40°C. Beyond this window, internal resistance rises and usable energy declines.

Ineffective thermal control can reduce usable battery capacity by 10–20%, particularly in cold climates or during sustained high-load operation. Battery enclosures directly influence how cooling systems are packaged, how heat is dissipated, and how evenly temperatures are maintained across the pack. Enclosures that enable uniform thermal conditions allow more of the battery’s rated capacity to be used in real-world driving.

Small Aerodynamic Gains, Real Range Impact

Battery enclosure geometry also affects vehicle packaging and aerodynamics. Flat, low-profile enclosures allow lower ride heights and smoother underbody airflow, helping reduce aerodynamic drag. Even modest improvements matter, as a 0.01 reduction in drag coefficient can improve highway range by 2–3%, especially at sustained speeds.

The Bigger Picture

As EV platforms move toward cell-to-pack and cell-to-chassis architectures, battery enclosures are no longer simple protective housings. They are becoming structural and efficiency-critical components that influence range, safety, and cost at the platform level. In a market where every additional kilometre matters, battery enclosure design has become a meaningful lever in EV performance optimisation.

TAGS: Automotive Mobility